|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-233-23

RIPPER SHANK REPLACEMENT - CONTINUED

0175 00

REMOVAL

WARNING

Use extreme caution when handling heavy parts. Provide adequate support and use assistance during pro-

cedure. Ensure that any lifting device used is in good condition and of suitable load capacity. Keep clear of

heavy parts supported only by lifting device. Failure to follow this warning may result in injury or death to

personnel.

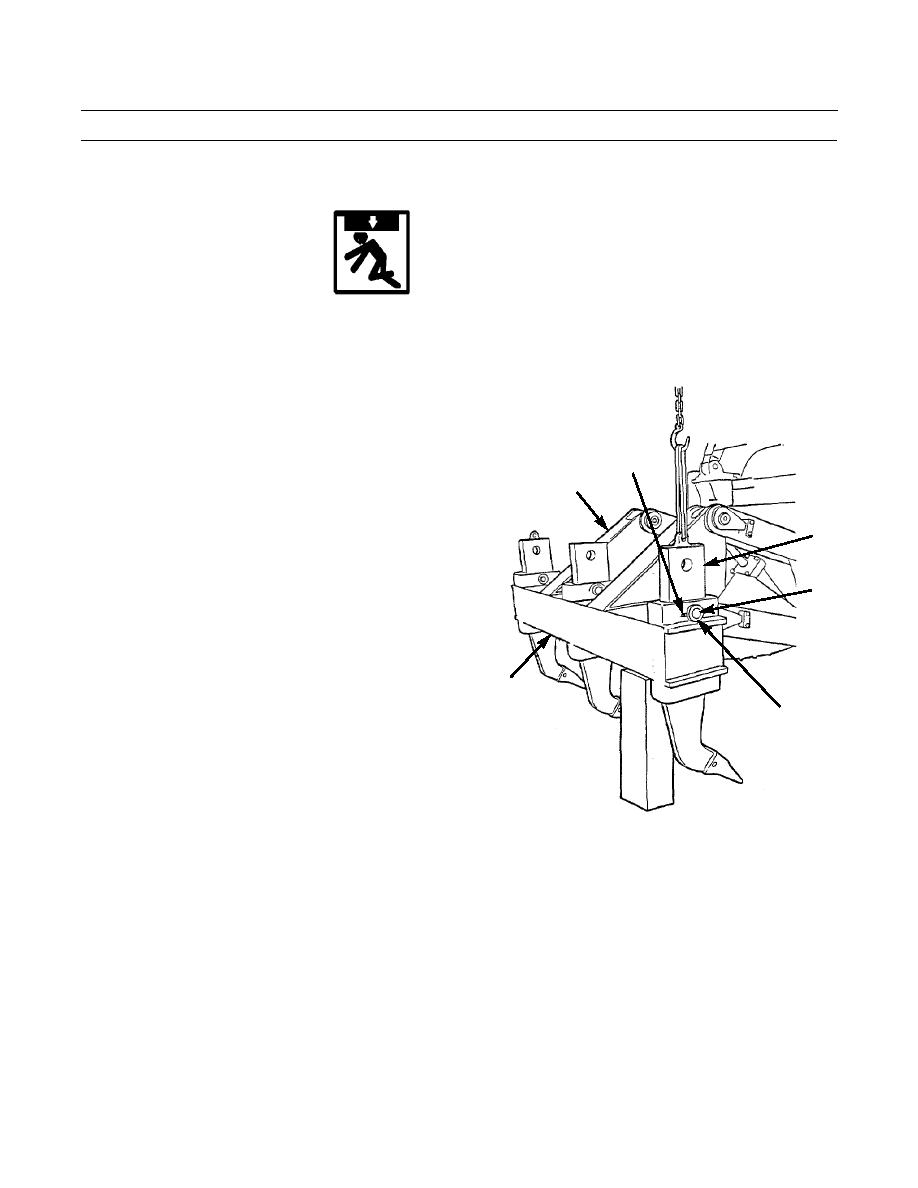

1.

Raise ripper (1) to its maximum raised position.

2.

Place suitable block(s) under beam (2) and shut down

engine.

5

NOTE

1

Ripper shank weighs 328 lb (149 kg).

3.

Attach a nylon sling and a suitable lifting device to

3

shank (3). Remove slack in lifting device.

4

2

6

386-587

NOTE

Use lifting device to take pressure off pin.

When removing center shank, remove cotter pins and retainers from both ends of pin. Push

pin to the right so that end of pin enters hole in ripper beam brace.

4.

Remove cotter pin (5) and retainer (6) from each end of pin (4). Discard cotter pins.

5.

Drive pin (4) from beam (2) and shank (3).

6.

Lower lifting equipment until shank (3) is resting on ground.

0175 00-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |