|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-233-23

BLADE AND PUSHARM ASSEMBLY REPLACEMENT - CONTINUED

0170 00

INSTALLATION - CONTINUED

WARNING

Do NOT remove hydraulic tank filler cap or disconnect or remove any hydraulic system line

or fitting unless hydraulic system pressure has been relieved. Hydraulic system pressure can

be over 2500 psi (17,237 kPa), even with engine and pump OFF. To relieve pressure, lower all

hydraulic attachments to the ground and shut down engine. Move control levers through all

operating positions, then SLOWLY loosen hydraulic tank filler cap. After maintenance,

tighten all connections before applying pressure. Escaping hydraulic oil under pressure can

penetrate the skin, causing serious injury or death.

At operating temperature hydraulic oil is hot. Allow hydraulic oil to cool before disconnecting

any hydraulics. Failure to do so could result in injury. Insert pipe nipple, located in tractor

toolbox, into hydraulic tank drain valve.

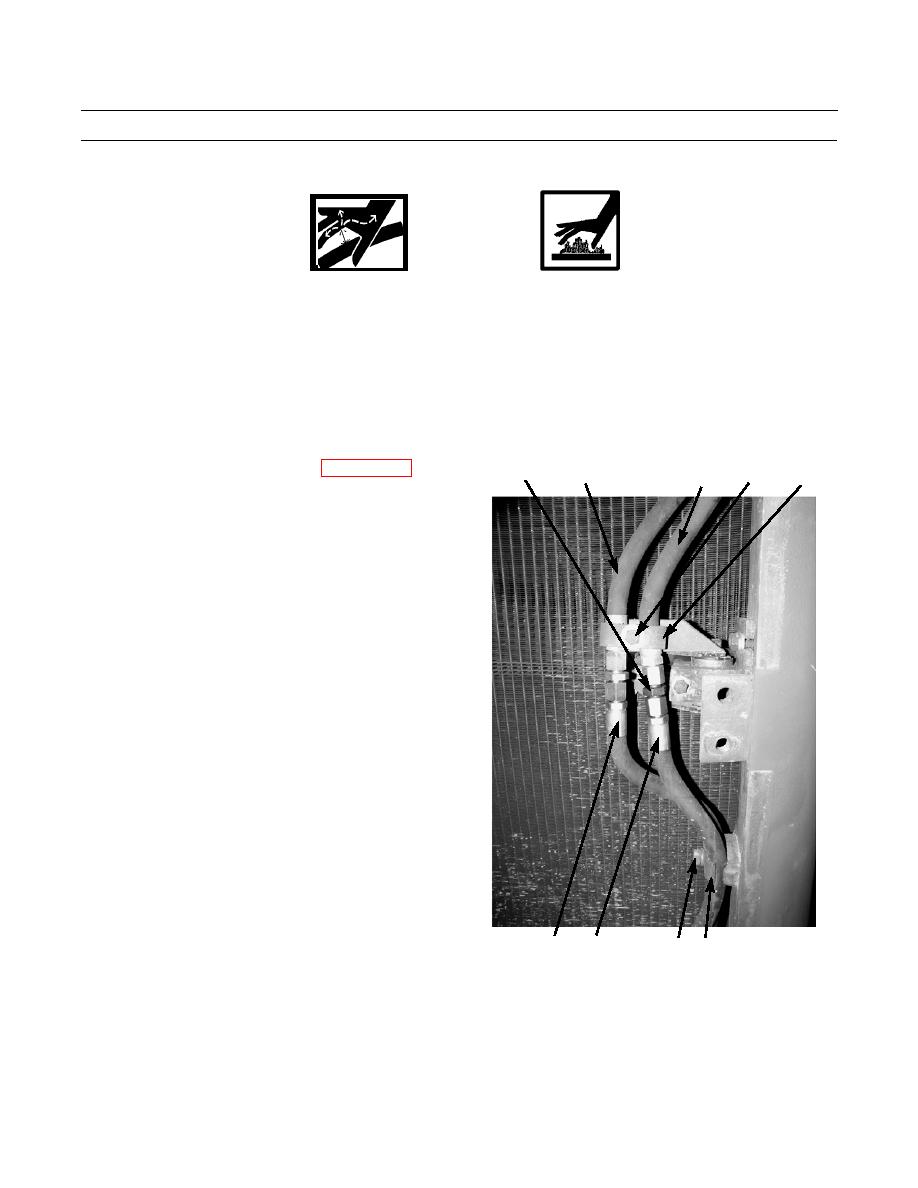

5.

Relieve hydraulic system pressure (WP 0176 00).

14

9

5,6,7

8

10

6.

Disassemble hose (13), nipple (14) and hose (12).

7.

Disassemble hose (10), nipple (15) and hose (9).

8.

Assemble hose (9), nipple (15) and hose (12).

9.

Assemble hose (10), nipple (14) and hose (13).

10.

Secure tilt cylinder hoses (12 and 13) to radiator guard

with clamp (11), new lockwasher (7) and bolt (6).

11.

Secure tilt cylinder hoses (9 and 10) to radiator guard

with clamp (8), bolt (6), new lockwasher (7) and nut

(5).

386-527

13

12

6,7 11

0170 00-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |