|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-233-23

HYDRAULIC PUMP REPAIR - CONTINUED

0149 00

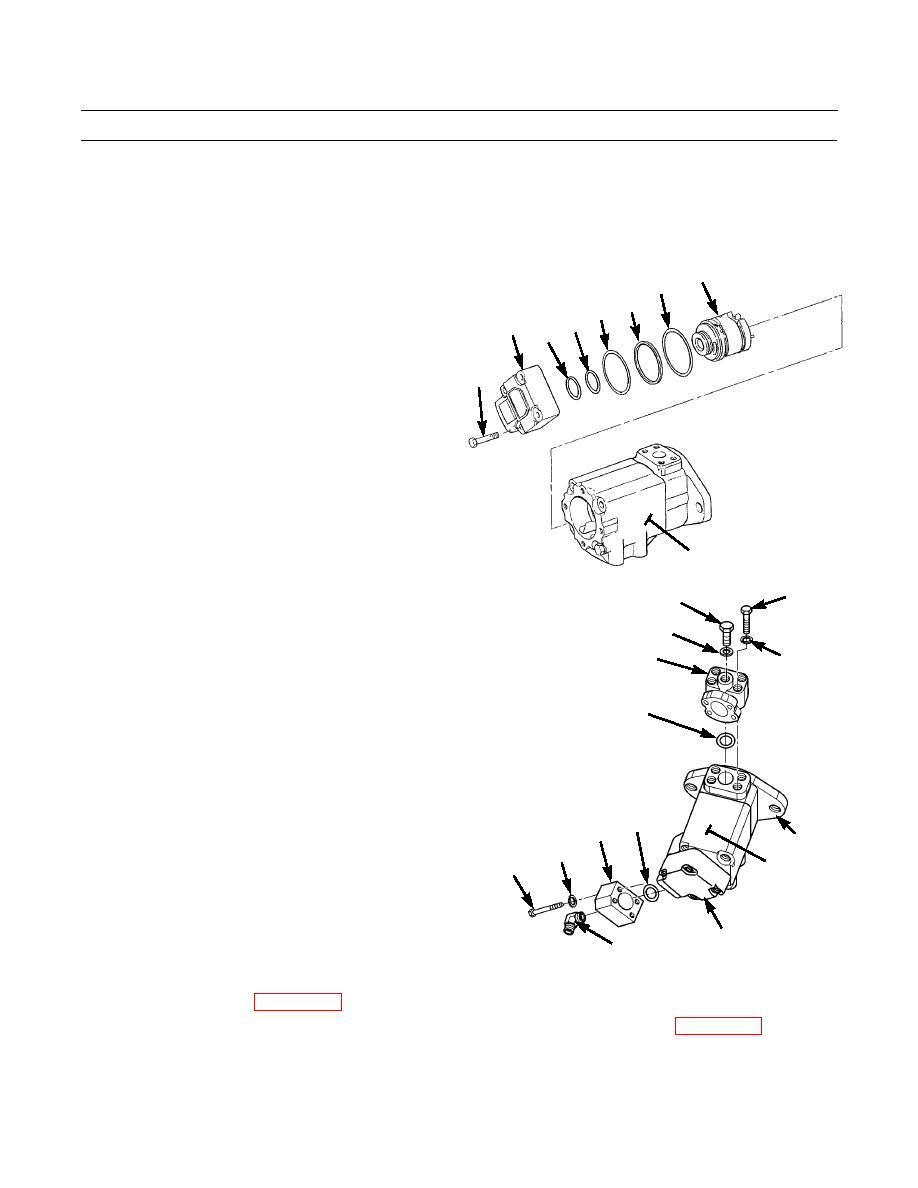

ASSEMBLY - CONTINUED

NOTE

Ensure cartridge assembly is assembled in the same orientation as noted during disassembly.

9.

Install new seal (20), new retainer (19), two new seals

21

20

(17 and 18) and washer (16) on front cartridge assem-

18 19

bly (21), with seals installed toward pressure source.

17

1

10.

Install front cartridge assembly (21) on end cover (1),

16

with cartridge positioned so pins in plate are in align-

ment with mounting holes in pump body (2).

15

11.

Install end cover (1) with four capscrews (15). Tighten

capscrews to 45 lb-ft (61 Nm).

2

386-672

NOTE

4

6

After assembly of pump, pump shaft must turn

7

by hand.

8

5

12.

Verify that pump shaft turns by hand. If not, pump

must be disassembled and assembled again.

13.

Install new O-ring (14) and tee (13) on end cover (1)

9

with four new lockwashers (12) and capscrews (11).

14.

Install elbow (10) on tee (13).

15.

Install new O-ring (9) and elbow (8) on top of front

pump housing (3). Secure with four new lockwashers

(5) and bolts (4).

14

16.

Install new O-ring (7) and plug (6) in elbow (8).

13

3

12

11

2

1

386-671

10

17.

Install hydraulic pump (WP 0148 00).

18.

Before returning machine to service, perform pump tests to ensure pump operation is correct (WP 0167 00).

END OF WORK PACKAGE

0149 00-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |