|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-233-23

TRACK ASSEMBLY INSPECTION AND ADJUSTMENT - CONTINUED

0120 00

ADJUSTMENT

NOTE

Track adjustment should be performed on level ground and on same surface conditions on

which machine is operated.

Packed dirt should not be removed from track, if packing conditions exist on the job.

1.

Move machine forward a distance of at least twice its length. Allow machine to coast to a stop. Do NOT apply brakes.

Shut down engine.

2.

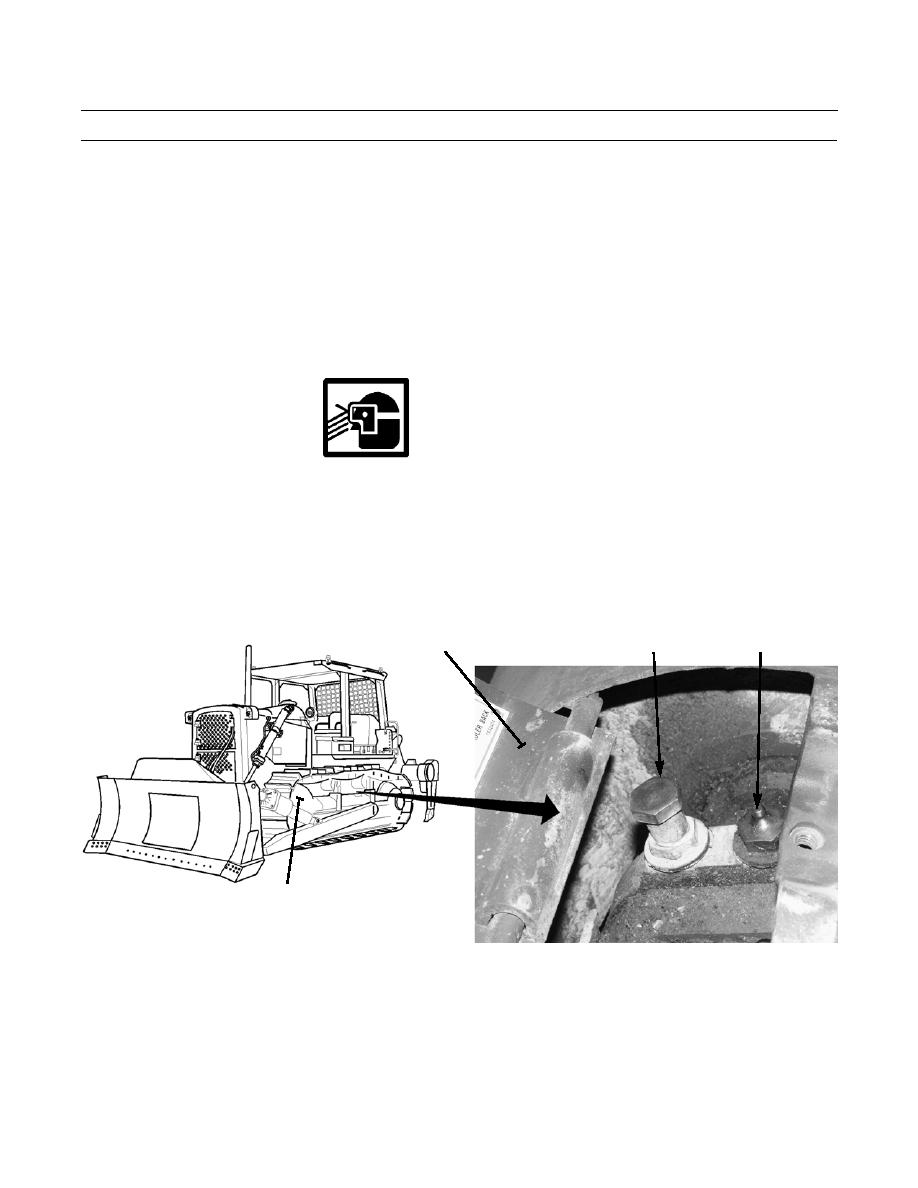

Loosen bolt and open recoil mechanism access cover (1).

3.

Wipe clean relief valve (2).

WARNING

Wear eye protection and keep face clear when venting grease from relief valve during track adjustment.

NEVER visually inspect relief valve to see if grease is escaping. Always observe track to see it has loosened.

Failure to follow this warning could cause eye injury or blindness.

4.

Open relief valve (2) and allow grease to escape and track tension to release.

5.

Close relief valve (2). Clean area around relief valve and fill valve (3).

6.

Connect grease gun to fill valve (3). Pump grease into fill valve until track idler (4) moves forward toward front of trac-

tor. STOP pumping when track idler stops moving.

2

3

1

4

386-717

0120 00-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |