|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-233-23

TRACK DRIVE SPROCKETS/HUBS REPLACEMENT - CONTINUED

0118 00

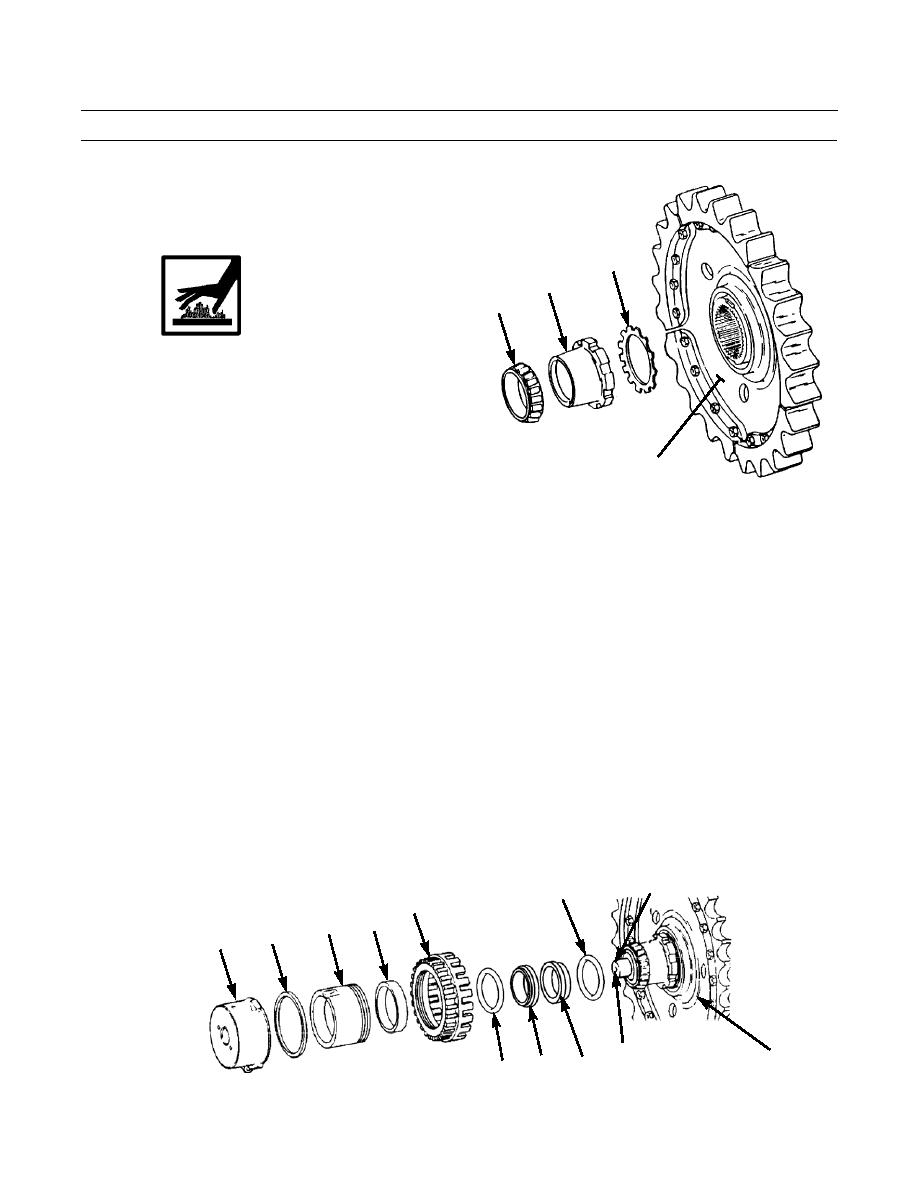

INSTALLATION - CONTINUED

14.

Install new retainer lock (28) and nut (29).

15.

Bend one tab of retainer lock (28) in notch of nut (29)

and one tab in notch of hub of sprocket (27).

28

29

30

WARNING

Use insulated gloves for handling hot parts to

avoid personal injury.

Heat bearing (30) to 275F (135C) maximum. Install

16.

bearing on final drive hub against nut (29).

27

386-280

17.

Lower temperature of bearing (30) and install bearing cup (24) in cage (23).

18.

Align slot in cage (23) over dowel in holder (17) and install cage in holder.

19.

Install new gasket (22) in groove in holder (17).

20.

Apply clean grease to threads of adjusting nut (18) and on face of nut that contacts gasket (22) in holder (17).

21.

Install adjusting nut (18) on holder (17) and tighten completely to end of thread travel.

CAUTION

New seal assemblies and new preformed packings must be used as matched pairs or failure

will result. Do not separate.

Seal and seal contact surfaces must be kept clean. Do NOT touch after being cleaned or leaks

can result.

NOTE

Do NOT apply oil to preformed packings.

22.

Install new seal assembly (20) and new preformed packing (21) inside adjusting nut (18). Clean metal contact surface of

seal assembly, then apply a thin film of clean oil to metal contact surface.

23.

Install new seal assembly (25) and new preformed packing (26) in hub of sprocket (27). Clean metal contact surface of

seal assembly, then apply a thin film of clean oil to metal contact surface.

24.

Install woodruff key (19) in sprocket shaft (8).

19 (HIDDEN)

26

18

24

23

22

17

8

27

25

20

21

386-279

0118 00-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |