|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-233-23

FINAL DRIVE PINIONS AND FLANGES MAINTENANCE - CONTINUED

0101 00

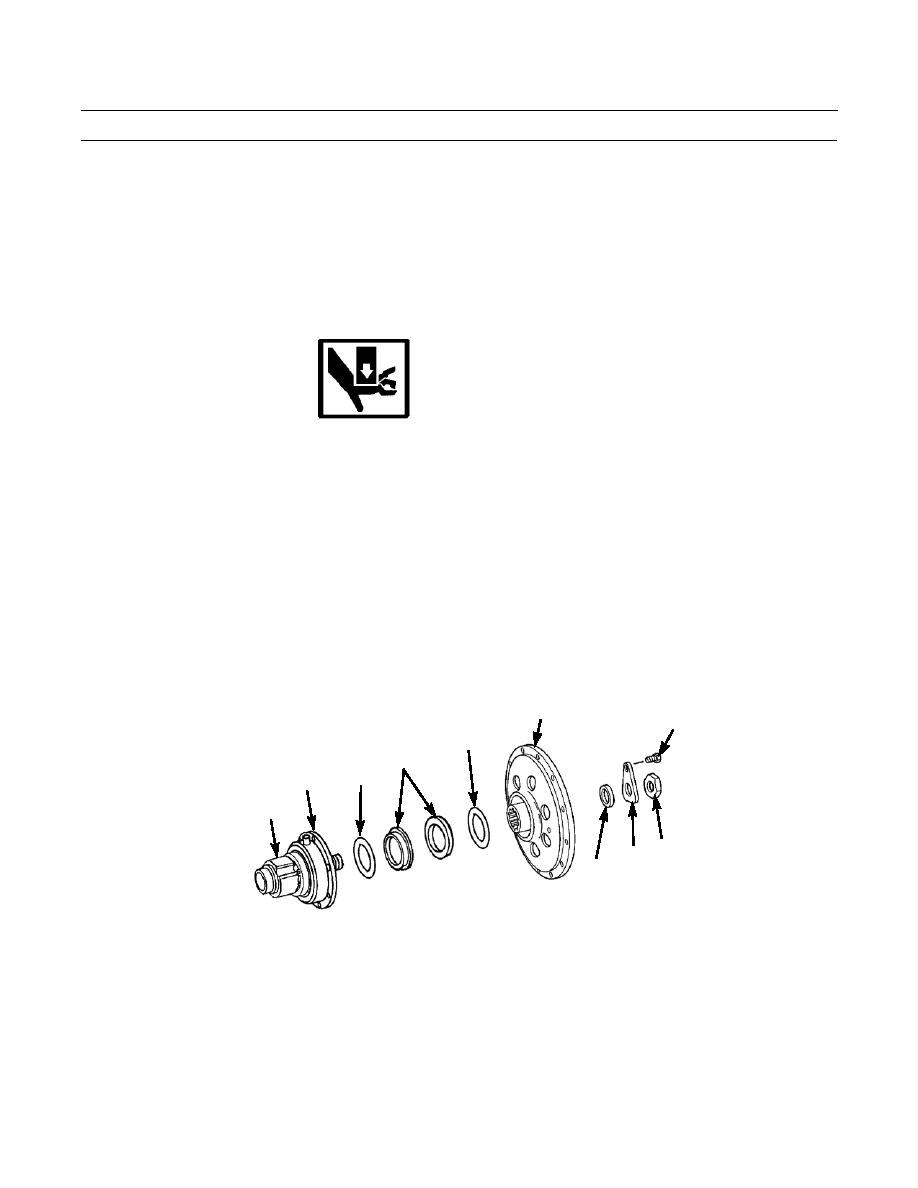

DISASSEMBLY

1.

Remove nut (2) from shaft of final drive pinion (6).

2.

Remove capscrew (7) and lock (8) from flange (1).

WARNING

Because flange is installed on shaft of final drive pinion with a force of 35-40 tons (312-356 kn), ensure nut

is installed to prevent flange from coming off and causing personal injury.

3.

Reinstall nut (2) on shaft of final drive pinion (6), with a distance of 0.125 in. (3.2 mm) between nut and flange (1).

WARNING

Keep hands clear of puller when removing flange. Failure to do so could cause injury.

4.

Install puller on flange (1) and apply pressure to break flange loose from shaft of final drive pinion (6).

5.

Remove puller, nut (2) and flange (1) from shaft of final drive pinion (6).

6.

Remove gasket (9) from hub of flange (1). Discard gasket.

NOTE

Duo-cone seal assembly is a two-piece seal. One half of seal is in flange (1); the other half is in bearing cage

(4).

7.

Remove retainer (10) with packing (11) from flange (1). Remove retainer (10) with packing (11) from bearing cage (4).

8.

Discard packings (11) and retainers (10).

9.

Remove bearing cage (4) from shaft of final drive pinion (6).

1

7

11

10

11

4

6

2

8

9

386-545

0101 00-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |