|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-233-23

TORQUE DIVIDER REPLACEMENT - CONTINUED

0092 00

REMOVAL

1.

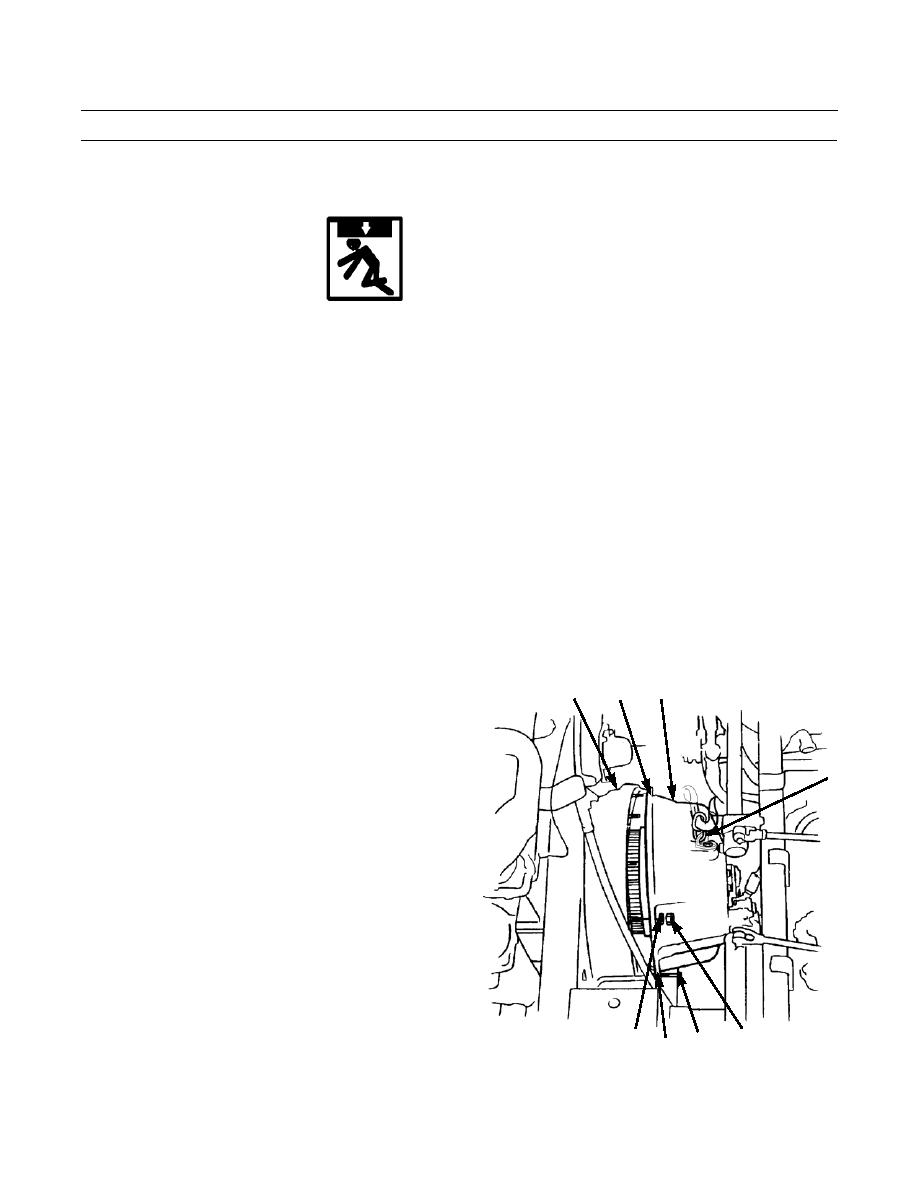

Fasten two lifting links (1) with 5/8 -11x 1-1/2 in. bolts to holes on top of torque divider (2).

WARNING

Use extreme caution when handling heavy parts. Provide adequate support and use assistance during pro-

cedure. Ensure that any lifting device used is in good condition and of suitable load capacity. Keep clear of

heavy parts supported only by lifting device. Failure to follow this warning may result in death or injury to

personnel.

NOTE

Torque divider weighs 300 lb (136 kg).

Use a suitable container to catch any oil that may drain from torque divider. Dispose of oil

IAW local policy and ordinances. Ensure all spills are cleaned up.

2.

Fasten a nylon sling and a suitable lifting device to lifting links (1).

3.

Remove 12 nuts (3) and lockwashers (4). Discard lockwashers.

4.

Install two 3/8 in. -16NC forcing screws (5) into torque divider (2) at locations (A).

5.

Slowly turn forcing screws (5) in until enough pressure is applied to separate torque divider (2) from flywheel housing

(6).

NOTE

Do NOT remove torque divider at this point.

6.

Back torque divider (2) away from flywheel housing

2

6

A

(6) just enough to slide a piece of wire around plane-

tary carrier. Connect each end of wire to forcing

screws (5). This will ensure that planetary carrier

assembly does not fall when torque divider is

1

removed.

7.

Slowly back torque divider (2) away from flywheel

housing (6) and lift out torque divider. Remove forc-

ing screws (5) from torque divider.

386-827

3

4

5

A

0092 00-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |