|

|||

|

|

|||

|

Page Title:

LOCATING TOP DEAD CENTER (TDC) COMPRESSION STROKE FOR NUMBER 1 PISTON (Cont) |

|

||

| ||||||||||

|

|

TM 5-2410-233-23

VALVE MECHANISM ADJUSTMENT- CONTINUED

0017 00

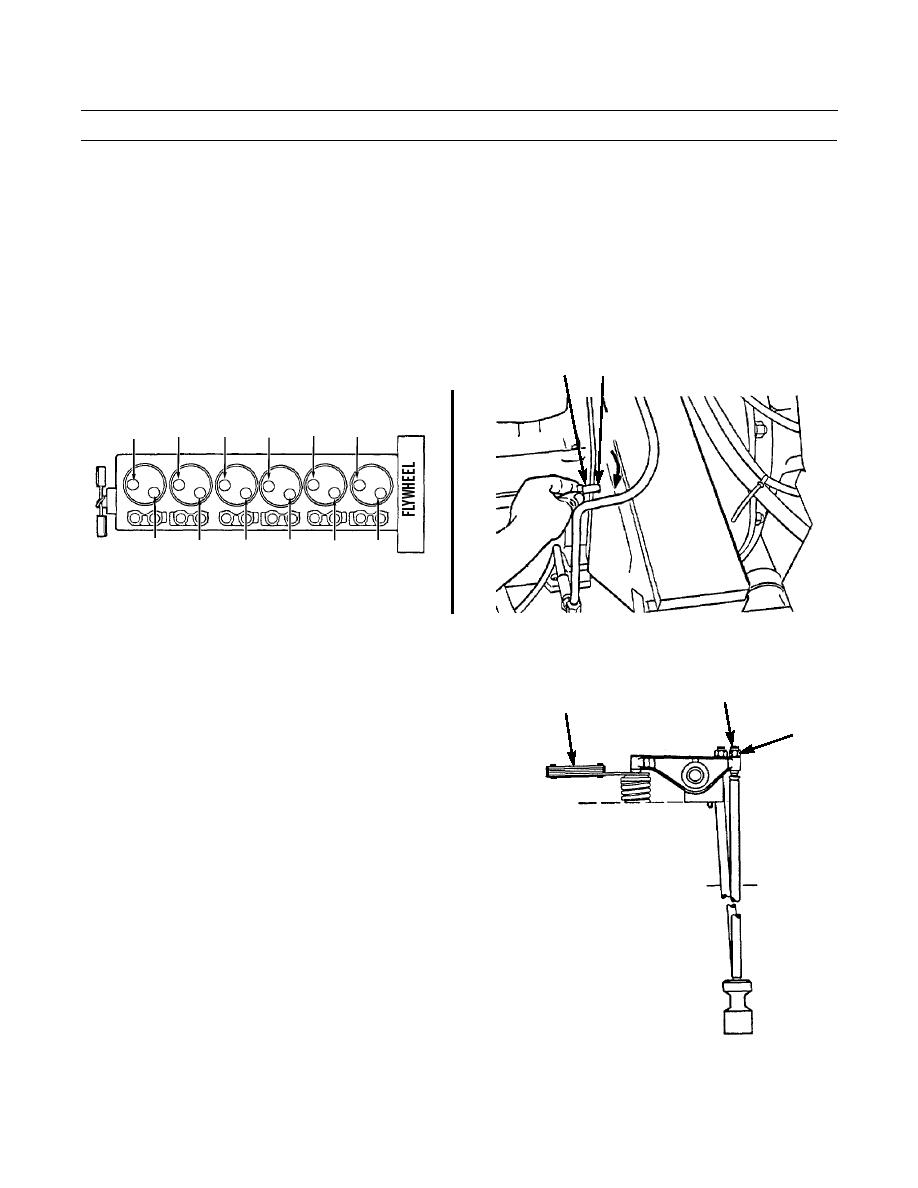

LOCATING TOP DEAD CENTER (TDC) COMPRESSION STROKE FOR NUMBER 1 PISTON - CONTINUED

NOTE

If piston is on compression stroke, valves will be closed on number 1 cylinder.

3.

Try moving rocker arms over cylinder number 1 up and down. If arms do not move, valves are open and piston is not on

compression stroke. Proceed to step 4.

4.

Remove bolt (25) and turn flywheel 360 degrees to the right. Return bolt to hole (26). Number 1 piston is now at TDC

on compression stroke.

26

25

EXHAUST VALVES

3

2

5

6

4

1

1

2

5

4

3

6

386-163

INTAKE VALVES

CYLINDER AND VALVE IDENTIFICATION

386-164

ADJUSTING VALVE CLEARANCE

28

FEELER GAGE

NOTE

27

Ensure pushrods are not bent before

performing adjustment.

When valve clearance is checked

using a feeler gage, it is NOT NECES-

SARY to adjust valves if measure-

ment falls within 0.022-0.028 in.

(0.56-0.71 mm) for exhaust and

within 0.012-0.018 in. (0.30-0.46 mm)

for intake.

1.

Loosen nut (27). Make adjustment to each valve by

using a flat-tipped screwdriver and turning adjustment

screw (28) to obtain correct reading with feeler gage.

2.

After adjustment for each valve has been made,

386-165

tighten nut (27) for valve adjustment screw (28) to 22

lb-ft (30 Nm), while holding screw.

0017 00-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |