|

|||

|

|

|||

|

Page Title:

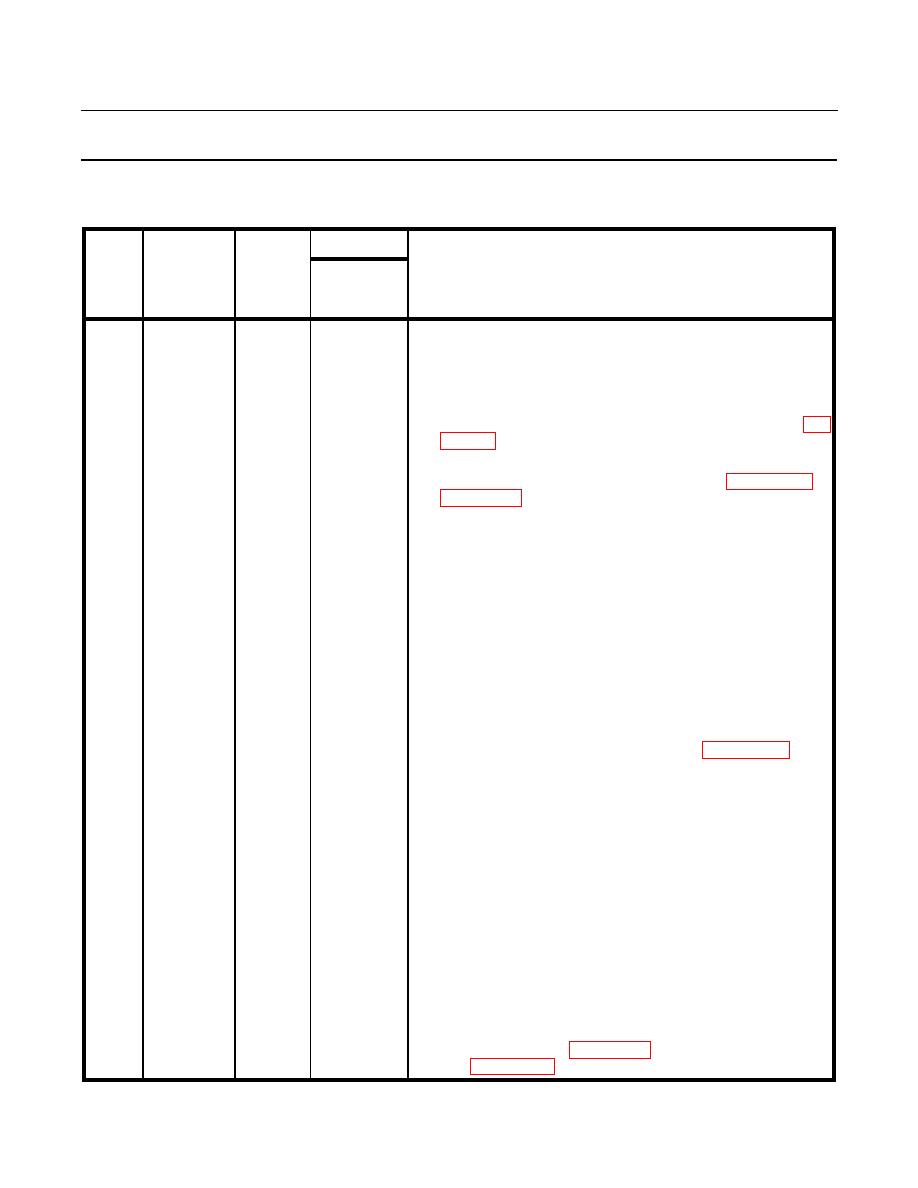

Table 1. Unit Maintenance Preventive Maintenance Checks and Services (PMCS) for the D7F Tractor. (Cont) |

|

||

| ||||||||||

|

|

TM 5-2410-233-23

UNIT MAINTENANCE PREVENTIVE MAINTENANCE CHECKS AND

SERVICES (PMCS) - CONTINUED

0009 00

Table 1. Unit Maintenance Preventive Maintenance Checks and

Services (PMCS) for the D7F Tractor - Continued.

LOCATION

ITEM TO

ITEM

MAN-

CHECK/

NO.

INTERVAL

HOURS

PROCEDURE

SERVICE

a.

Inspect equalizer bar for cracks, bends, breaks and loose or

20

Semiannual

Undercar-

missing mounting hardware.

riage and

Tracks

b.

Inspect track roller guards for cracks, bends and wear.

c.

Inspect the following components: track roller frame, idlers,

track rollers, track carrier rollers and sprockets. Replace compo-

nents that are damaged or worn beyond acceptable limits (WP

d.

Check recoil spring and track adjuster cylinder for damage or

external leakage of grease. Replace as needed (WP 0113 00 or

e.

Inspect for damage or wear to track links and bushings. Inspect

for cracked or missing track shoes. Replace any component that

is broken, cracked, missing or worn beyond acceptable limits.

NOTE

The D7F uses two types of tracks: The Caterpillar

"branded track" (identified by a Caterpillar logo) and the

"classic track" (identified by a pictorial symbol of a track

link). Inspection criteria and maintenance of both styles of

tracks are the same. However, components of these tracks

are NOT completely interchangeable. Before maintenance

and requisitioning of parts, verify the type of track on the

tractor and proceed accordingly.

f.

Check and adjust track tension if necessary (WP 0120 00).

a.

Follow routing of lines, hoses and tubing for hydraulic system.

21

Semiannual

Hydraulic

Inspect for loose fittings, cracks, bends, breaks and leaks.

System

b.

Inspect blade lift cylinders and tilt cylinder and cylinder hydrau-

lic lines for secure mounting, loose fittings and leaks.

c.

If equipped with ripper, inspect ripper lift cylinders and cylinder

hydraulic lines for secure mounting, loose fittings and leaks.

d.

If equipped with winch, inspect winch hydraulic lines for secure

mounting, loose fittings and leaks.

CAUTION

22

Semiannual

Bulldozer

Blade

If wear to cuttings edge and end bits is sufficient to cause

wear to blade support, change cutting edge and install new

end bits.

Inspect cutting edge and end bits for damage, wear or loose or miss-

ing mounting hardware. Change cutting edge if damaged or worn to

less than 3/4 in. (19 mm) (WP 0169 00). Install new end bits if worn/

damaged (WP 0169 00).

0009 00-9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |