|

|||

|

|

|||

|

Page Title:

Coolant in Engine Lubricating Oil. |

|

||

| ||||||||||

|

|

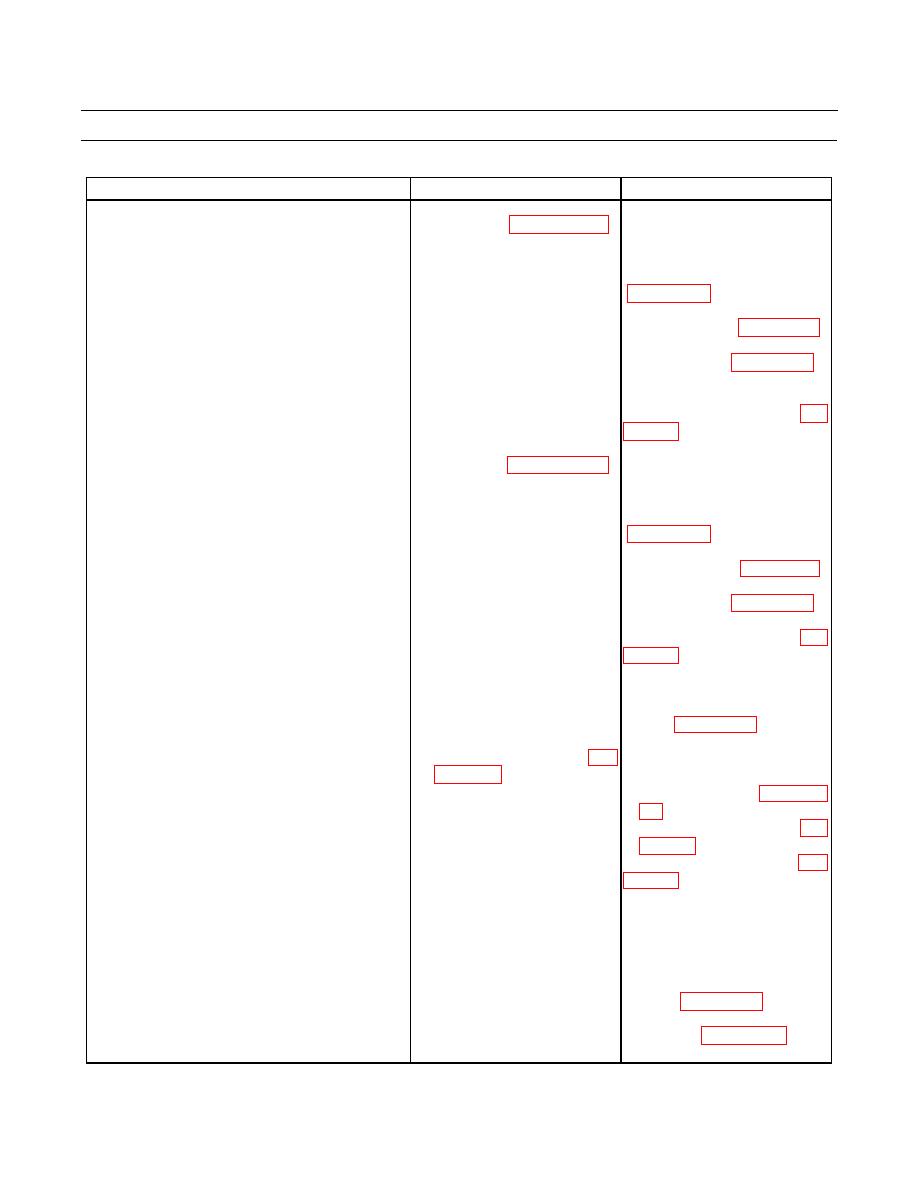

TM 5-2410-233-23

TROUBLESHOOTING PROCEDURES - CONTINUED

0006 00

Table 1. Engine Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. Remove

cylinder

head

19. Coolant in Engine Lubricating Oil.

Assembly (WP 0023 00).

Inspect cylinder head for the

following:

a. Leaking head gasket.

Replace a damaged head gasket

b. Damaged cylinder head or Replace damaged cylinder head

spacer plate.

and/or spacer plate (WP 0023 00).

block Replace engine assembly if

2. Inspect

cylinder

assembly and liners for cracks are found (WP 0019 00).

cracks.

3. Inspect engine oil cooler for If internal damage or leaking is

signs of damage.

suspected, replace oil cooler (WP

1. Remove

cylinder

head

20. Engine Lubricating Oil in Cooling System.

assembly (WP 0023 00).

Inspect cylinder head for the

following:

a. Leaking head gasket.

Replace a damaged head gasket

b. Damaged cylinder head or Replace damaged cylinder head

spacer plate.

and or spacer plate (WP 0023 00).

2. Inspect

cylinder

block Replace engine assembly if

assembly for cracks.

cracks are found (WP 0019 00).

3. Inspect engine oil cooler for If internal damage or leaking is

signs of damage.

suspected, replace oil cooler (WP

1. Inspect engine for slobbering Run engine under full load for 30

21. Engine Lubricating Oil at Exhaust.

at turbocharger.

minutes at operating temperature.

2. Inspect exhaust side of Replace turbocharger is oil leak is

turbocharger for signs of oil present (WP 0046 00).

leak.

3. Remove cylinder head (WP 1. Replace

cylinder

head

assembly if valve guides are

damaged or worn valve

worn or damaged (WP 0023

guides.

2. Replace engine assembly (WP

22. Engine Cranks But Will Not Start in Cold 1. Check ether canister by Replace canister if empty (WP

removing from valve. Shake 0057 00).

Weather (Fuel System Operating Properly).

canister and listen for liquid

splashing inside.

2. Check starting aid valve for Refer to Table 6, Electrical

proper operation.

Trouble-shooting.

3. Check starting aid valve tube 1. If tube assembly is not

assembly and fittings for

damaged, replace starting aid

damage.

valve (WP 0057 00).

2. Replace

damaged

tube

assembly (WP 0057 00).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |