|

|||

|

|

|||

|

Page Title:

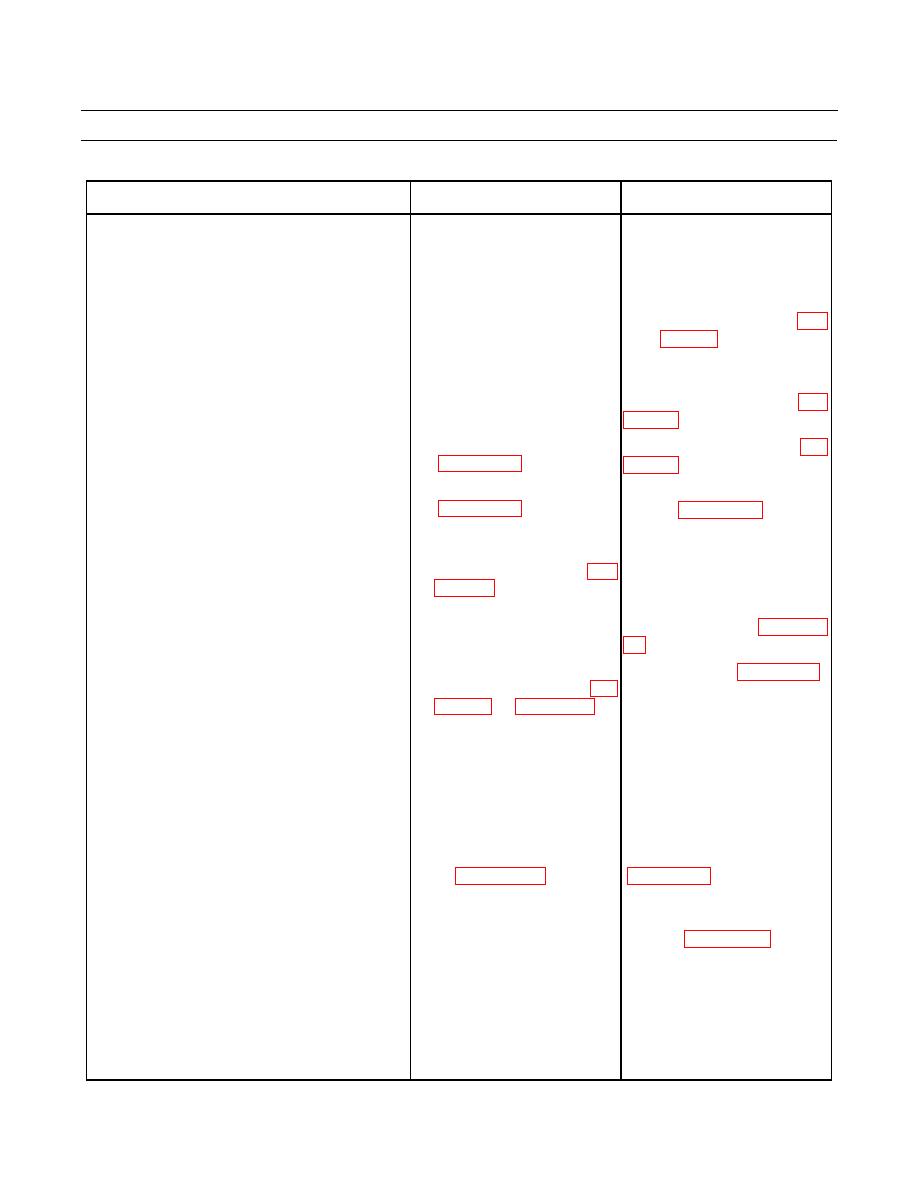

Table 1. Engine Troubleshooting Procedures |

|

||

| ||||||||||

|

|

TM 5-2410-233-23

TROUBLESHOOTING PROCEDURES - CONTINUED

0006 00

Table 1. Engine Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

a. If a leak is at a connection,

Engine Cranks But Fails to Start - Continued. 4. Inspect fuel lines and

2.

tighten connection.

connections for leaks and/or

damage.

b. If a leak results from

cracked, split or damaged

line, replace lines (WP

5. Inspect governor linkage for If linkage does not operate

proper

operation

and properly or is out of adjustment,

adjustment.

Adjust governor linkage (WP

6. Check fuel injection timing Adjust fuel injection timing (WP

7. Perform cylinder cutout test Replace nozzle for suspect

cylinder (WP 0037 00).

If shaft does not rotate, remove

8. Check for slipping fuel

injection

pump

drive.

small cover from timing gear

Remove access cover (WP

cover and tighten accessory drive

gear retaining nut. If tightening

look through fuel transfer

corrects slipping condition, time

pump mounting openings to

fuel injection pump (WP 0057

see if pump shaft rotates.

1. In cold weather, ensure proper Replace engine oil (WP 0010 00).

3.

Engine Cranks Slowly, Hard to Start.

engine oil is being used (WP

2. Check starting circuits. Refer

to

Electrical

Trouble-

shooting, Table 6.

Engine Starting Motor Operates, Does Not Check for broken or damaged

4.

teeth on flywheel assembly and

Engage Flywheel Ring Gear.

starter drive.

a. Remove starting motor Replace defective starting motor

starter motor drive.

b. Manually turn engine and Replace defective flywheel

inspect flywheel ring gear assembly (WP 0028 00).

teeth through starting

motor opening in flywheel

housing.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |