|

|||

|

|

|||

|

Page Title:

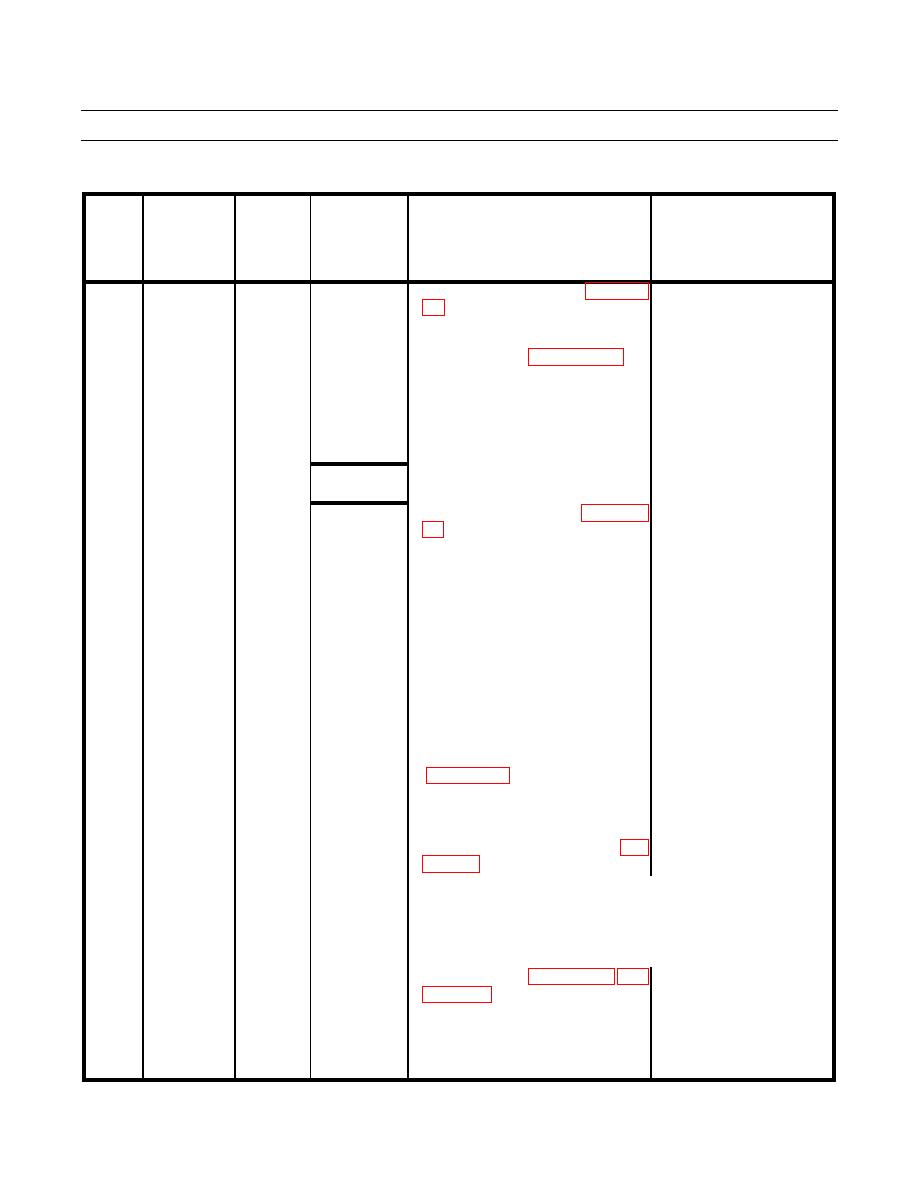

Table 1. Operator Preventive Maintenance Checks and Services (PMCS) for D7F Tractor - Continued. |

|

||

| ||||||||||

|

|

TM 5-2410-233-10

OPERATOR PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS) - CONTINUED

0012 00

Table 1. Operator Preventive Maintenance Checks and Services (PMCS) for D7F Tractor - Continued.

LOCATION

ITEM TO

ITEM

MAN-

CHECK/

NOT FULLY MISSION

NO.

INTERVAL

HOURS

SERVICE

PROCEDURE

CAPABLE IF:

13

e. Add oil (Item 8, 9 or 10, WP 0019

(Con't)

on dipstick is between ADD and

FULL lines on dipstick. Refer to

correct grade of oil for expected

temperature range.

f. Reinstall dipstick.

g. Reinstall filler cap and turn to the

right until tight.

OPERATOR

STATION

a. Occupy and adjust seat (WP 0004

14

Before

Seat, Seat

Belt, Gages

and

b. Check all gages and indicators for Damage is evident that

Indicators

damage.

would impair operation.

c. Check for damage to governor and Damage is evident that

steering clutch levers, brake pedals would impair operation.

and decelerator pedal. There should

be free movement.

d. If equipped with winterized cab,

check for broken or damaged

windows. Ensure windows are

clean, to ensure an unobstructed

view.

e. Start engine and allow to warm up

f. Ensure all indicators and gages are Needle is in RED zone on

functioning properly. Be sure to gage.

check fuel pressure gage on right

side of engine compartment (WP

WARNING

Use of seat belt while operating machine is mandatory. Fas-

ten belt BEFORE operating machine. Trying to fasten seat

belt during operation creates a hazardous condition. Failure

to follow this warning may result in injury or death.

g. Fasten seat belt (WP 0005 00, page Seat belt is missing or will

belt is snug across lap with buckle in

the middle.

h. Check operation of flood lights and

dash lights.

0012 00-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |