|

|||

|

|

|||

|

Page Title:

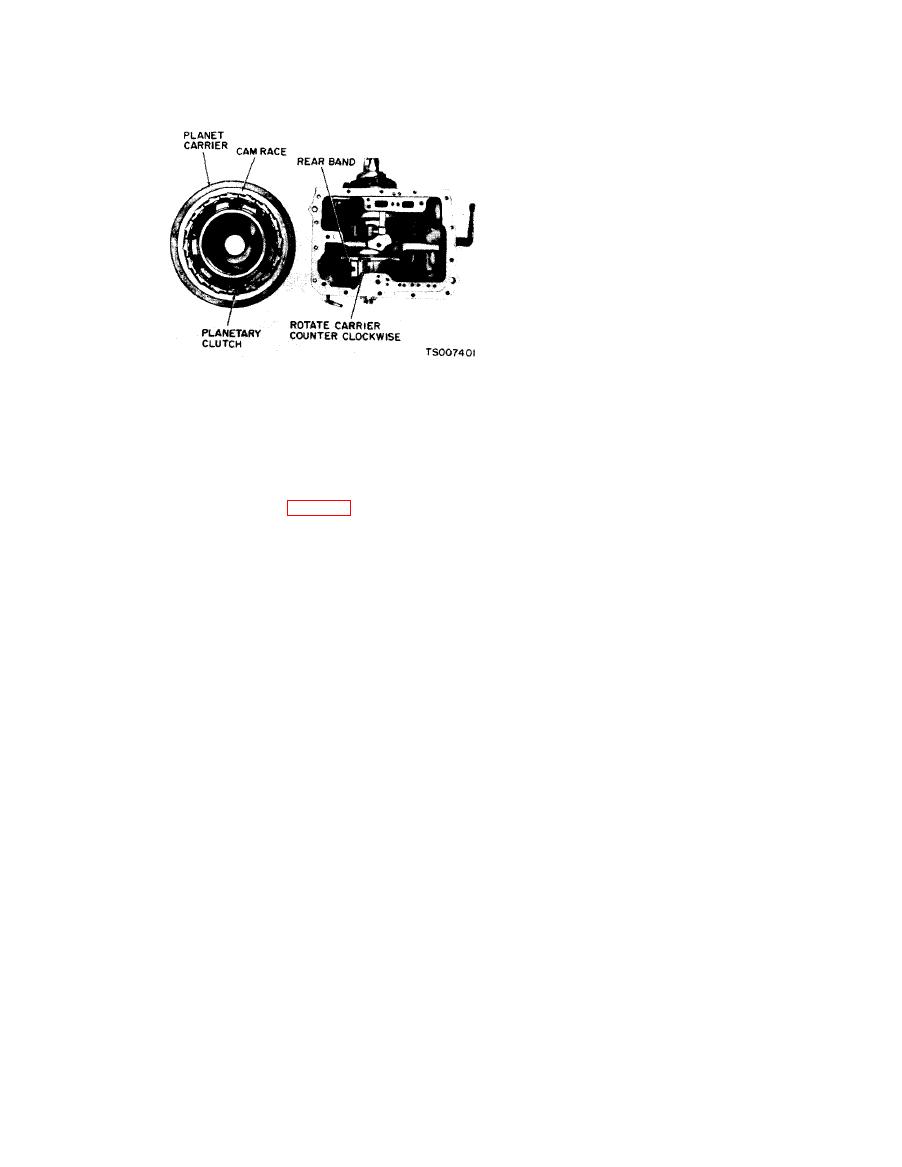

Figure 7-13. Planetary Clutch Installation. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

(17) Install the governor assembly, aligning

the groove with the ball in the output shaft.

(18) Install the governor with the governor

body plate toward the rear of the transmission.

Install the governor snap ring.

(19) Place the four seal rings in the

distributor sleeve, and check the ring gap.

(20) Check the fit of the seal rings in the

grooves in the output shaft. The rings should

rotate freely. Install the rings in the grooves of

the output shaft.

(21) Install the three tubes in the distributor

sleeve.

(22) Install the distributor sleeve on the

output shaft, wit h the chamfer facing forward.

.

Lubricate the parts to facilitate assembly. Slide

the sleeve over the four rings and at the same time

(8) Carefully position the planet carrier on

start the tubes into the case. The distributor

the center support. Move the carrier forward until

sleeve is located between the governor snap ring

the clutch rollers are felt to contact the bearing

and speedometer drive gear.

surface of the center support.

(23) Make sure that the speedometer drive

(9) While applying forward pressure on the

gear lock ball is in place, then install the gear.

planet carrier, rotate it counterclockwise, as

(24) Install the output shaft ball bearing

viewed from the rear (fig. 7-13). This will cause

front spacer and the output shaft ball bearing

the clutch rollers to roll toward the large opening

with the snap ring toward the rear,

end of the cams in the race, compressing the

(25) Install the output shaft rear spacer and

spring slightly, so that the rollers will ride up the

the speedometer drive gear.

chamfer on the planetary support and onto the

(26) Install the rear bearing retainer gasket

inner race.

and the retainer. Torque the bolts to specifi-

(10) Push the planet carrier all the way

cations.

forward.

(27) Install the brake drum and companion

(11) Check the operation of the planetary

flange. Torque the nut to 150-200 ft/lb. Tighten

clutch by rotating the carrier counterclockwise. It

the nut to the nearest cotter pin hole, and install

should rotate counterclockwise (viewed from the

the cotter pin.

rear) with a slight drag, and it should lock up

(28) Position a new front pump gasket in the

when attempting to rotate it in a clockwise

counterbore of the transmission case.

direction.

(29) Install the front pump, aligning the

(12) Install the selective thrust washer on

pump bolt holes with the holes in the case. Install

the pinion carrier rear pilot. If the end play was

three of the front pump attaching bolts and

not within specifications when checked prior to

torque them to 17-22 ft/lb.

disassembly, replace the washer with one of

(30) Mount dial indicator support in a front

proper thickness. Refer to TM 10-3930-633-34P

pump bolt hole. Mount a dial indicator on the

for selective thrust washer thicknesses.

support so that the contact rests on the end of

(13) Install the output shaft, carefully

turbine shaft.

meshing the internal gear with the pinions.

(31) Pry the output shaft all the way forward

( 1 4 ) With the center support properly

by using a screwdriver between the large internal

assembled, position the rear pump drive key in

gear and the case.

the keyway on the output shaft.

(32) Lightly block the output shaft in the

(15) Position new front and rear gaskets on

forward position to eliminate all output shaft end

the pump body. Retain the gaskets with trans-

play.

mission fluid. Then install the rear pump. Be

(33) Move the pinion carrier all the way

sure the drive key is aligned with the keyway in

forward by inserting a screwdriver between the

the pump drive gear.

planet carrier and the large internal gear and

(16) Position the governor drive ball in the

prying against the case. Maintain slight forward

pocket in the output shaft. Retain the ball with

pressure, and set the dial indicator at zero.

transmission fluid.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |