|

|||

|

|

|||

|

Page Title:

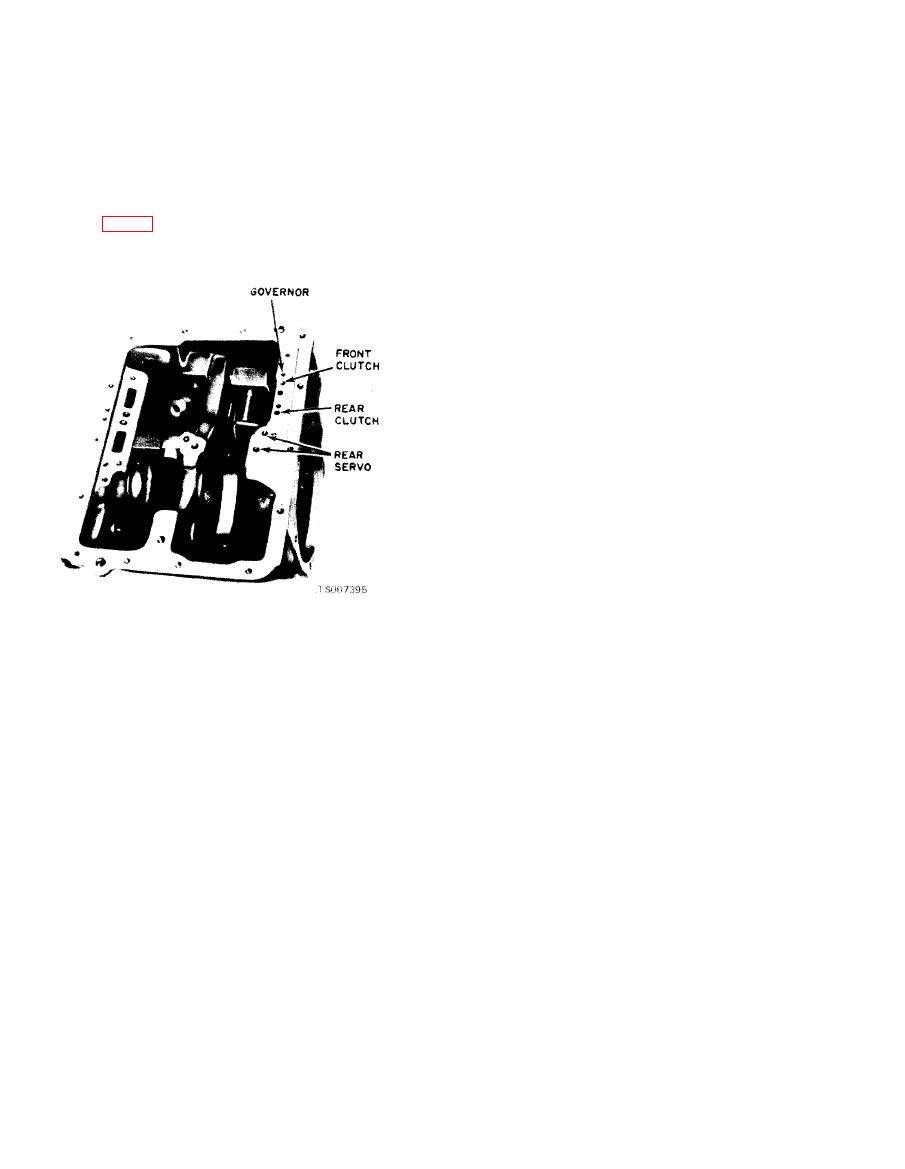

Figure 7-6. Air Pressure Checks. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

b. Test Set-up. To make the air pressure

clutch or operates both clutches at once, remove

checks, loosen the oil pan bolts and lower one

and, with air pressure, check the fluid passages in

edge of the oil pan to drain the transmission fluid.

the case and front pump to detect obstructions.

Remove the pan and the control valve body

assembly. The inoperative units can be located by

a. Check the governor inspection plate on the

introducing air pressure into the transmission

extension housing for leakage. Replace gasket if

case passages leading to the clutches, servos, and

leakage is apparent.

governor (fig. 7-6). 50-75 PSI pressure is suf-

b. Leakage at the oil pan gasket often can be

ficient for purposes of this test.

stopped by tightening the attaching bolts to the

proper torque. If necessary, replace the gasket.

c. Check the fluid filler tube connection at the

transmission case or pan. If leakage is found here,

install a new O-ring or tighten the fitting to the

specified torque.

d. Check the fluid lines and fittings between

the transmission and the cooler in the radiator

tank for looseness, wear, or damage. If leakage

cannot be stopped by tightening a fitting, replace

the damaged parts.

e. Check the engine coolant in the radiator. If

transmission fluid is present in the coolant, the

cooler in the radiator is probably leaking.

f. The cooler can be further checked for leaks

by disconnecting the lines from the cooler fittings

and applying 50-75 PSI air pressure to the fit-

tings. Remove the radiator cap to relieve the

pressure build-up at the exterior of the oil cooler

tank. If the cooler is leaking and will not hold

pressure, the radiator must be replaced. See TM

10-3930-633-12.

c. Front Clutch. Apply air pressure to the

g. If leakage is found at either the downshift

transmission case forward clutch or front clutch

control lever shaft or the manual lever shaft,

passage. A dull thud can be heard when the clutch

replace either or both seals.

piston is applied. If no noise is heard, place the

h. Inspect the pipe plug on the left side of the

fingertips on the input shell or clutch cylinder,

transmission case at the front. If the plug shows

and again apply air pressure to the forward or

leakage, torque the plug to specifications. If

front clutch passage. Movement of the piston can

tightening does not stop the leaks, replace the

be felt as the clutch is applied.

plug.

d. Rear Clutch. Apply air pressure to the rear

i. When a converter drain plug leaks, remove

clutch passage. A dull thud indicates that the

the drain plug with a six-point wrench. Coat the

reverse-high or rear clutch piston has moved to

threads with oil-resistant sealer and install the

the applied position. If no noise is heard, place the

plug. Torque the drain plug to specification. Fluid

fingertips on the clutch drum and again apply air

leakage from the converter housing may be

pressure to detect movement of the piston.

caused by engine oil leaking past the rear main

e. Governor. Remove the governor inspection

bearing or from oil gallery plugs. Be sure to

cover from the extension housing. Apply air

determine the exact cause of the leak before repair

pressure to the front clutch passage. Listen for a

procedures are started.

sharp click, and watch to see if the governor

weight snaps inward. Inward weight movement

premixed at the rate of teaspoon of dye powder

indicates correct governor valve operation.

to pint of transmission fluid have proved

f. Rear Servo. Apply pressure to the rear

helpful in locating the source of the fluid leakage.

servo apply passage. Movement of the servo

Such dyes may be used to determine whether an

indicates correct operation. If servo does not

engine oil or transmission fluid leak is present or

operate, remove, disassemble and repair.

if the fluid in the oil cooler leaks into the engine

g. Test Results. If air pressure applied to

coolant system. A black light, however, must be

either of the clutch passages fails to operate a

used with the fluorescent dye solution.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |