|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-633-34

excessively burned areas in the exhaust outlet

ports.

(2) Check the cylinder head for cracks and

inspect the gasket surface for burrs and nicks.

Replace the head if it is cracked.

FREE TURNING

SPRING RETAINER

(3) When a cylinder head has been removed

due to gasket leakage, check the cylinder head

gasket surface for flatness, using a straightedge

laid across the surface. A feeler gage can be used

under the straightedge to determine warpage.

The cylinder head must measure flat within 0.006

inches in any 6 inches of length, or within 0.007

inches overall. The cylinder head may be planed.

and ground up to 0.010 inch to correct a warped

surface.

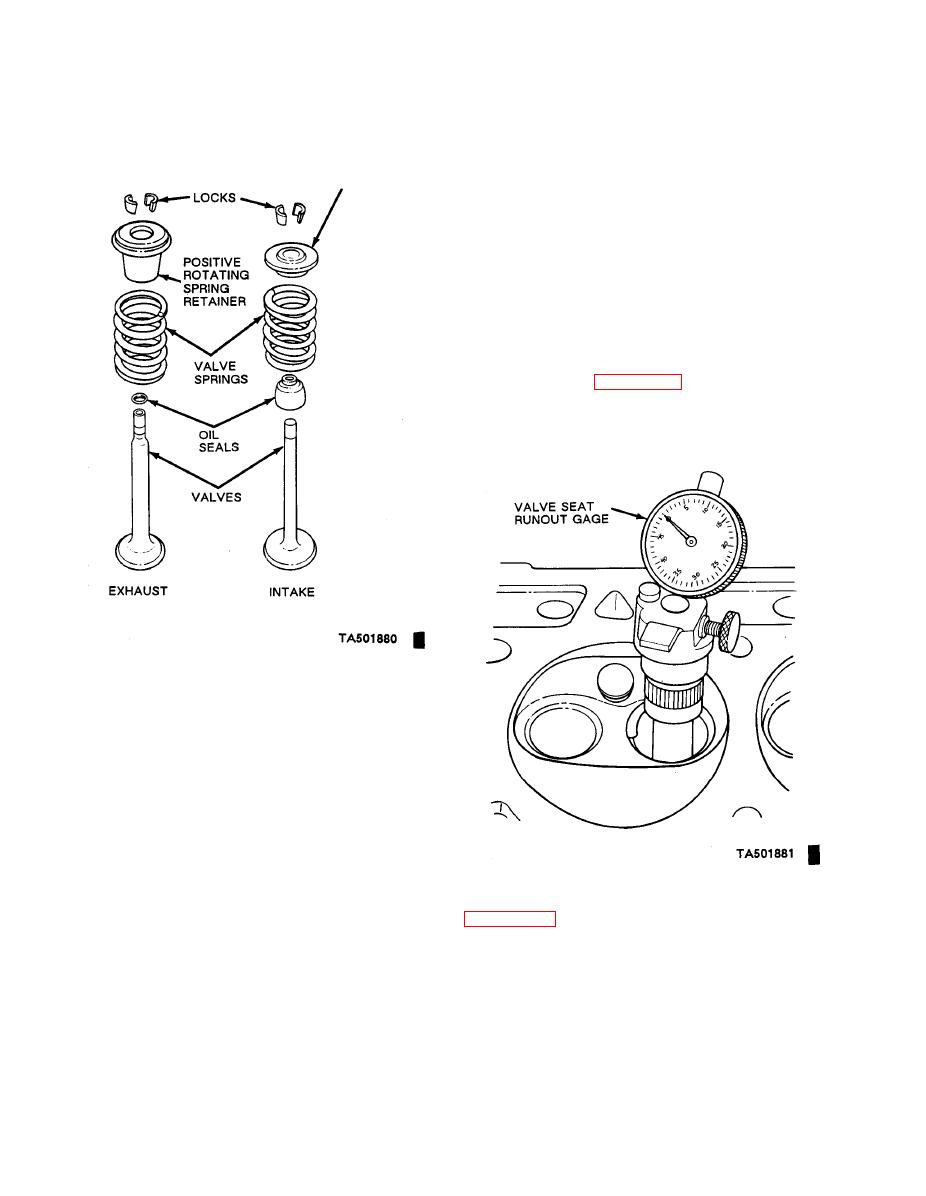

(4) Check valve seat runout, using a runout

gage as shown in figure 6-10. Valve seat runout

must not exceed 0.0015 inch. If the reading ex-

ceeds this figure, both valve and seat must be

refaced.

6-15. Cylinder Head Cleaning and Inspection

a. Cleaning.

(1) With the valves installed to protect the

valve seats, remove deposits from the combustion

chambers and valve heads with a scraper and a

wire brush.

CAUTION

Be careful not to damage the cylinder

head gasket surface.

(2) After valves are removed, clean the valve

guide bores with a valve guide cleaning tool.

(5) Check valve seat width, as shown in

Using cleaning solvent to remove dirt, grease and

between 0.060 and 0.080 inch, while exhaust

other deposits. clean all bolt holes.

valve seats should measure 0.070 to 0.090 inches.

(3) Remove all deposits from the valves with

Valve seats must be refaced if seat width is not

a fine wire brush or buffing wheel.

within specifications.

b. Inspection.

(1) Inspect the cylinder heads for cracks or

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |