|

|||

|

|

|||

|

Page Title:

Table 6-1. Manifold Vacuum Readings. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

Gage Reading (inches Hg)

Engine Condition

(See footnote at end of Table)

Normal.

17 or more.

Low and steady.

Loss of power in all cylinders caused by late ignition or valve timing, or loss of

compression due to leakage mound the piston rings.

Very low.

Manifold. carburetor or cylinder head gasket leak.

Needle fluctuates steadily as speed increases.

A partial or complete loss of power in one or more cylinders caused by: a

leaking valve, cylinder head or intake manifold gasket leak, a defect in the

ignition system or a weak valve spring.

Gradual drop in reading at engine idle.

Excessive back pressure in the exhaust system.

_

-

Intermittent fluctuation.

An occasional loss of power possibly caused by a defect in the ignition system

or a sticking valve.

Slow fluctuation or drifting of the needle.

Improper idle mixture adjustment, or carburetor spacer or intake manifold

gasket leak.

NOTE

Allowance should be made for the effect of altitude on the gage reading. The engine vacuum will decrease with an increase in altitude.

b. Procedure.

(1) Be sure the battery is good. Operate the

engine until normal operating temperature is

Maximum

Minimum

PSI

PSI

reached. Turn the ignition switch off. Loosen the

spark plugs, blow out any dirt in the spark plug

wells, then remove the plugs.

(2) Set the carburetor throttle and choke

plates in the wide open position.

(3) Install a compression gage in No. 1

cylinder.

(4) Crank the engine (with the ignition

switch off) at least five (5) pumping strokes and

record the highest reading indicated. Note the

approximate number of compression strokes

required to obtain the highest reading.

.

d. Diagnosis. If one, or more, cylinders read

(5) Repeat the check on each cylinder

low, squirt approximately one (1) tablespoon of

cranking the engine approximately the same

engine oil on top of the pistons in the low reading

number of compression strokes.

cylinders. Repeat compression pressure check on

compression

c. Results. T h e indicated

these cylinders.

pressures are considered normal if the lowest

(1) If compression improves considerably,

reading cylinder is within 75 percent of the

the piston rings are at fault.

highest. Refer to table 6-2 for pressure limits

(2) If compression does not improve, valves

between cylinders. Variations exceeding 75

are sticking or seating poorly.

percent implies an improperly seated valve or

(3) If two adjacent cylinders indicate low

worn or broken piston rings.

compression pressures and squirting oil on the

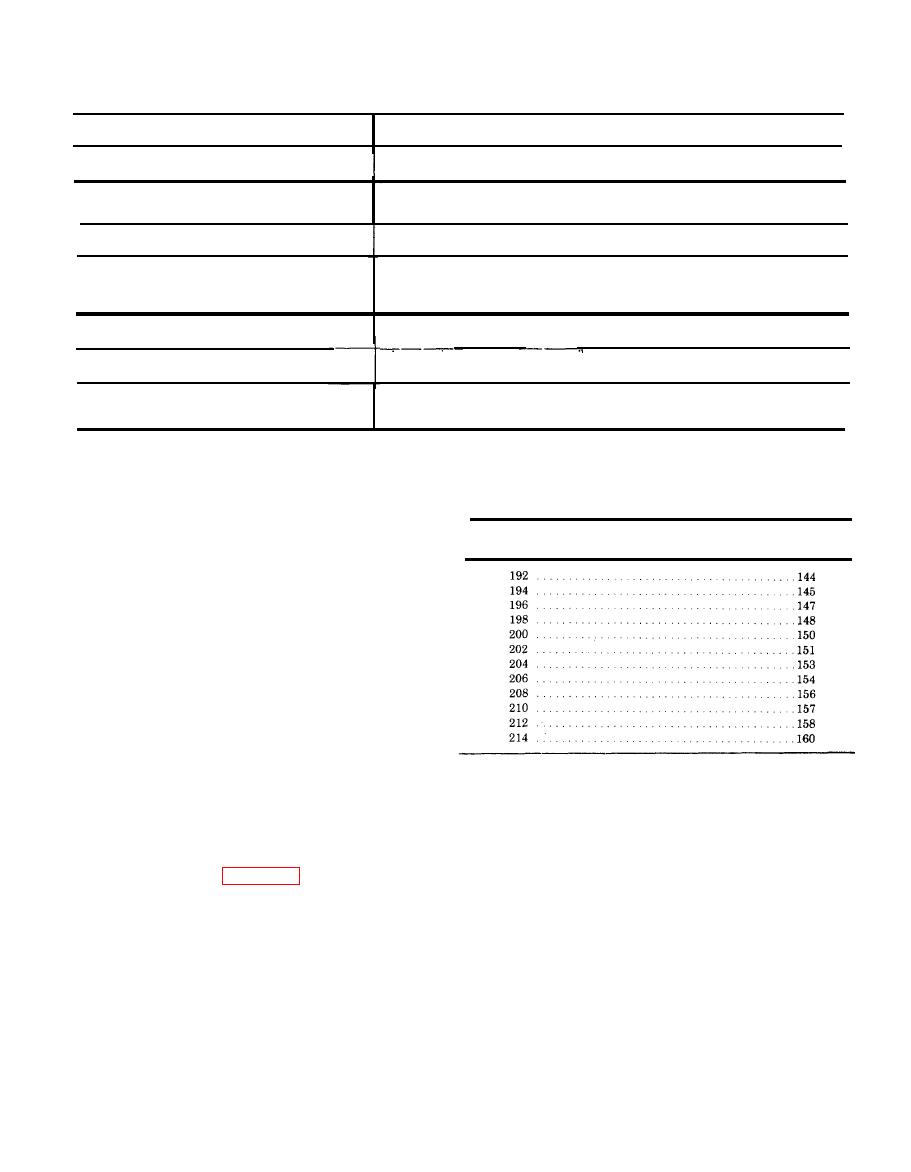

Table 6-2. Compression Test Pressure Limits.

pistons does not increase the compression, the

Minimum

Maximum

cause may be a cylinder head gasket leak between

PSI

PSI

the cylinders. Engine oil and/or coolant in the

186 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...140

188 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...141

cylinders could result from this problem.

190 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...142

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |