|

|||

|

|

|||

|

Page Title:

Section III. PREVENTIVE MAINTENANCE CHECKS AND SERVICES |

|

||

| ||||||||||

|

|

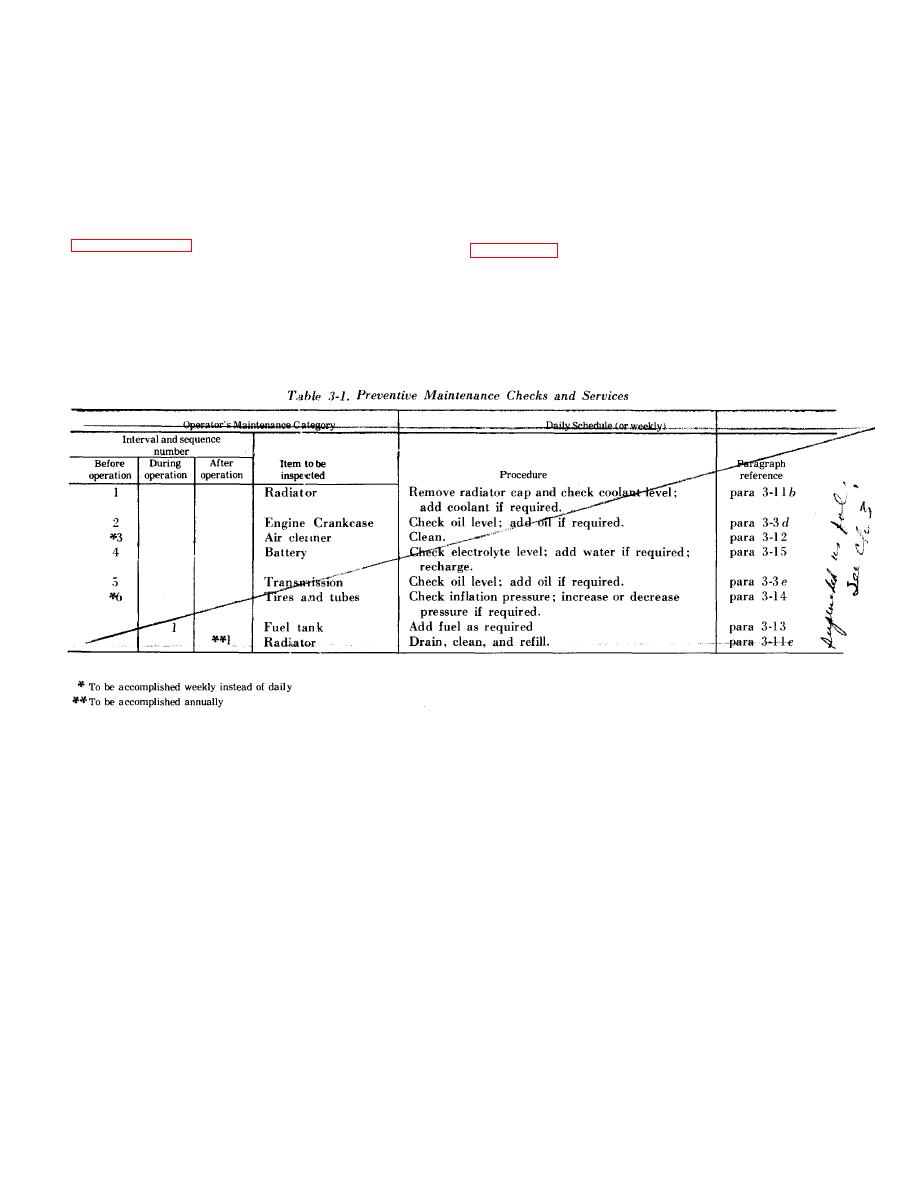

Section III. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

3-4. General

were continued. R e c o r d a l l d e f i c i e n c i e s a n d

shortcomings together with the corrective action

To insure that the tractor is ready for operation at

taken on DA Form 2404 (Equipment Inspection

all times, it must be inspected systematically so that

and Maintenance Worksheet) at the earliest

d e f e c t s may be discovered and corrected before

possible opportunity.

t h e y result in serious damage or failure. The

necessary preventive maintenance c h e c k s a n d

Preventive Maintenance Checks and

services to be performed are listed and described in

Services

T a b l e 3-1 contains a tabulated listing of the

sequence of minim urn inspection requirements.

operator's periodic (daily and weekly) preventive

Defects discovered during operation of the unit will

maintenance c h e c k s a n d s e r v i c e s . T h e i t e m

be noted for future correction, to be made as soon

numbers are listed consecutively and indicate the

as operation has ceased. Stop operation im-

sequence of minimum requirements.

mediately if a deficiency is noted during operation

which would damage the equipment if operation

Section IV. OPERATOR'S TROUBLESHOOTING

3-6. General Observation of Tractor Operation

3-7. Operator's Troubleshooting

You should always be alert for improper operation

Chart 3-1 contains information that will be useful

of the tractor. You will not be able to correct any

to you in troubleshooting. M a l f u n c t i o n s a n d

major t r o u b l e since parts a n d too Is are not

c o r r e c t i v e actions which are beyond the scope

authorized at the operator level. Observe the

authorized for the operator are not included in the

trouble carefully so that you can give a n accurate

chart. If the trouble cannot be corrected by ap-

report to organizational maintenance personnel.

plying the "corrective action", report the trouble to

This will save time and effort in getting your tractor

organizational maintenance personnel.

back into good running condition.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |