|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-364-20-1

Allow engine to cool before performing troubleshooting maintenance. If necessary use insulated pads

and gloves. Hot engine components will burn and cause personnel injury.

Do not use any other procedures in this manual (except for the suggestions listed below and Fault

steps) when trying to solve an intermittent problem. Use of any other procedures for this kind of

problem CAN result in the replacement of non-defective parts. Many intermittent problems are

caused by faulty electrical connectors or wiring. Diagnosis must include a careful inspection of

the indicated wiring and connectors. Example: an intermittent Code 35 (Oil Pressure Sensor Voltage High)

should cause suspicion of a problem in the following areas associated with the Oil Pressure Sensor.

1. Wire 530 (signal line), Wire 416 (+5 volt line) or Wire 452 (ground line).

2. The Oil Pressure Sensor connector or DDEC ECM connector.

3. An intermittent in the Oil Pressure Sensor (least likely).

DDEC ECM connector terminals are easily damaged. Use care when connecting and disconnecting

connectors.

NOTE

The following steps should only be

used if troubleshooting was started

at DDEC II Troubleshooting (All

Conditions) and you were referred here.

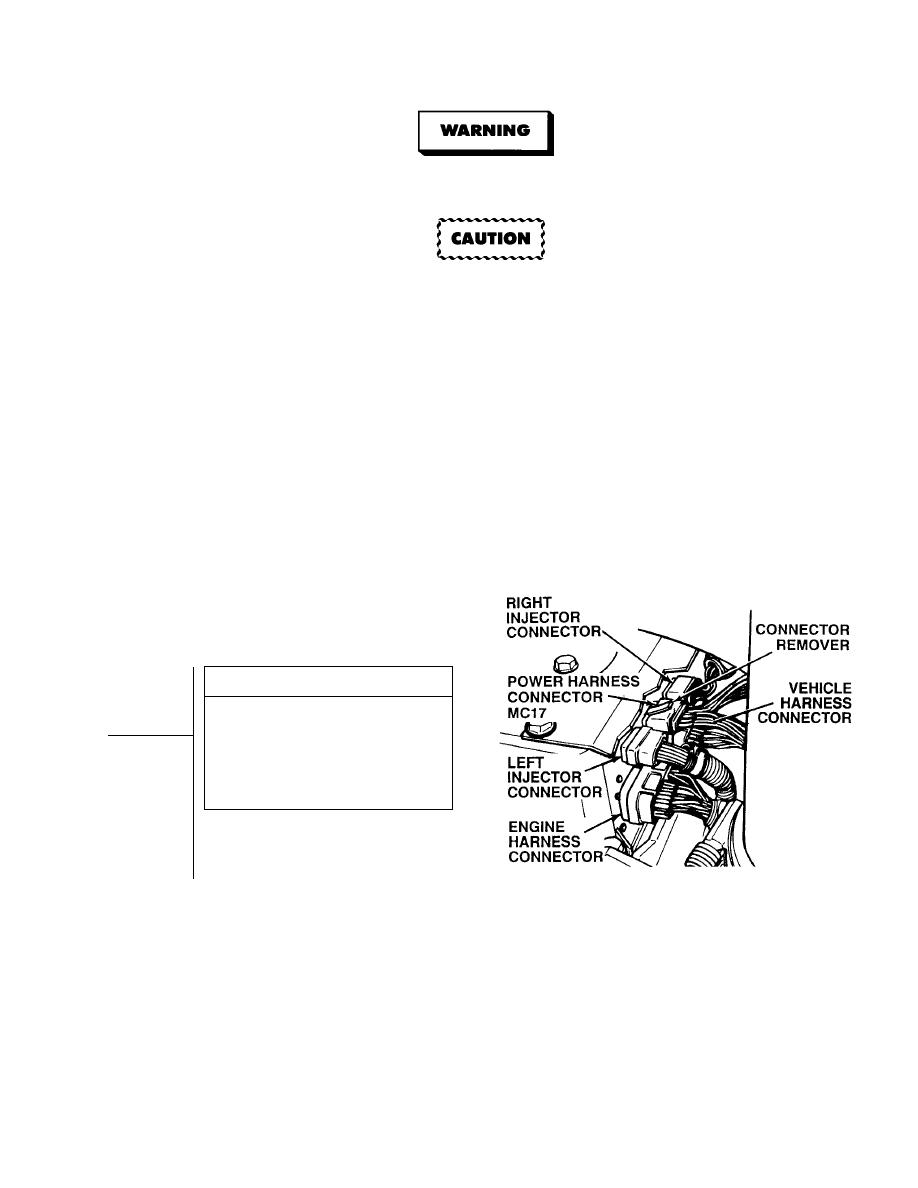

VISUAL INSPECTION

Inspect all DDEC ECM connectors for

proper alignment and seating.

(1) If connectors are not seated

properly, reseat and go to Step 2

of this Fault.

(2) If connectors are seated properly,

go to Step 2 of this Fault.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |