|

|||

|

|

|||

|

Page Title:

Engine Crankcase Pressure (Blowby) - Test |

|

||

| ||||||||||

|

|

TM 9-2320-312-24-2

Testing and Adjusting Section

Turbocharger Failure

i01281928

Engine Crankcase Pressure

(Blowby) - Test

Personal injury can result from air pressure.

SMCS Code: 1215; 1317

Personal injury can result without following prop-

Table 12

er procedure. When using pressure air, wear a pro-

Tools Needed

tective face shield and protective clothing.

Part

Part Name

Quantity

Maximum air pressure at the nozzle must be less

Number

than 205 kPa (30 psi) for cleaning purposes.

8T-2700

1

Blowby/Air Flow Indicator

If a turbocharger failure occurs, remove the air-to-air

Damaged pistons or damaged rings can cause

aftercooler core. Internally flush the air-to-air

too much pressure in the crankcase. This condition

aftercooler core with a solvent that removes oil

will cause the engine to run rough. There will be

and other foreign substances. Shake the air-to-air

more than the normal amount of fumes (blowby)

aftercooler core in order to eliminate any trapped

rising from the crankcase breather. The breather

debris. Wash the aftercooler with hot, soapy water.

can then become restricted in a very short time.

Thoroughly rinse the aftercooler with clean water

This condition can cause oil leakage at gaskets and

and blow dry the aftercooler with compressed air.

seals that would not normally have leakage. Blowby

Blow dry the assembly in the reverse direction of

can also be caused by worn valve guides or by a

normal air flow. To make sure that the whole system

failed turbocharger seal.

is clean, carefully inspect the system.

Note: The electronic service tool can be used to

NOTICE

measure crankcase pressure.

Do not use caustic cleaners to clean the air-to-air af-

tercooler core.

Caustic cleaners will attack the internal metals of the

core and cause leakage.

Dynamometer Test

In hot ambient temperatures, chassis dynamometer

tests for models with an air-to-air aftercooler can

add a greater heat load to the jacket water cooling

system. Therefore, the jacket water cooling system's

temperature must be monitored. The following

measurements may also need a power correction

g00286269

factor:

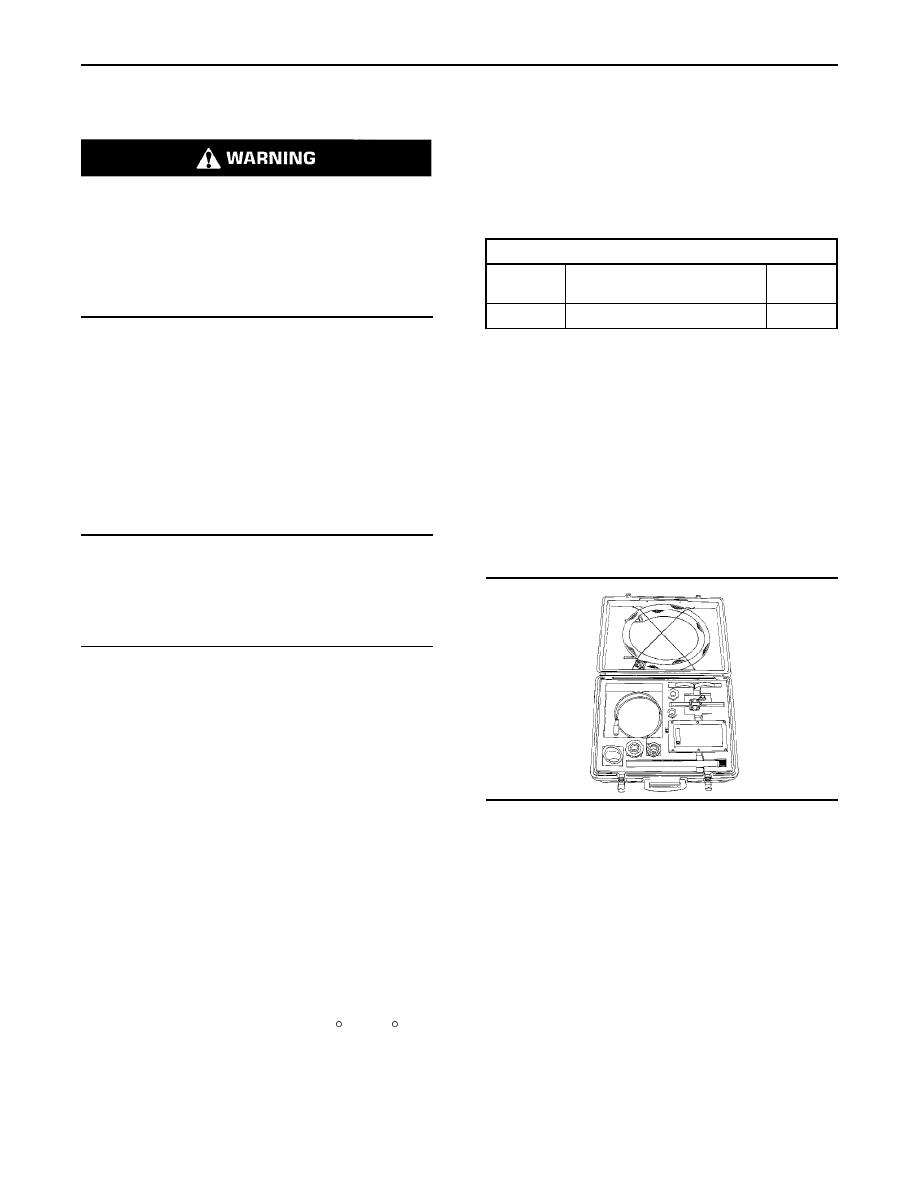

Illustration 62

8T-2700 Blowby/Air Flow Indicator

Inlet air temperature

The 8T-2700 Blowby/Air Flow Indicator is used

Fuel API rating

to check the amount of blowby. Refer to Special

Instruction, SEHS8712, "Using the 8T-2700

Fuel temperature

Blowby/Air Flow Indicator" for the test procedure

for checking the blowby.

Barometric pressure

With dynamometer tests for engines, use the

FT-1438 Aftercooler (Dynamometer Test). This tool

provides a water cooled aftercooler in order to

control the inlet air temperature to 43 C (110 F).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |