|

|||

|

|

|||

|

Page Title:

CODE 57 XX -- RANGE VERIFICATION C3 PRESSURE TEST |

|

||

| ||||||||||

|

|

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

CODE 57 XX -- RANGE VERIFICATION C3 PRESSURE TEST

(BETWEEN SHIFTS)

Main code 57 indicates failure of the range verification C3 pressure switch test. This test determines if the C3

pressure switch is closed when it should be open. The test occurs when a range is commanded that does not use the

C3 clutch (neutral, 1, 2, 4, and 6). The code is set if the C3 pressure switch is closed when it should be open. If C3

clutch comes on when not needed, three clutches are applied and a transmission tie-up occurs. The ECU will

command a range which does use the C3 clutch and activate the DO NOT SHIFT response.

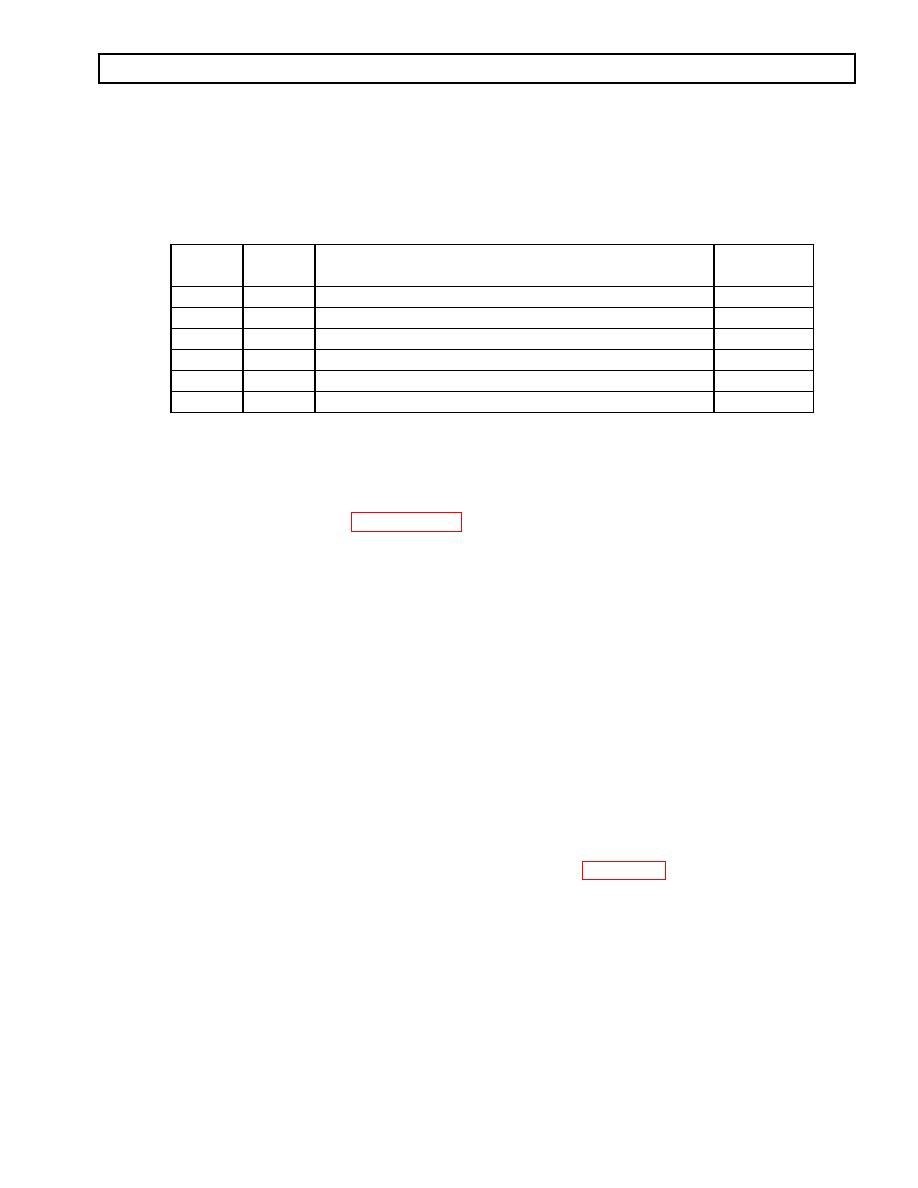

Main

Replace

Code

Subcode

Meaning

57

11

Range verification C3 pressure switch while in 1st

B

57

22

Range verification C3 pressure switch while in 2nd

C

57

44

Range verification C3 pressure switch while in 4th

C

57

66

Range verification C3 pressure switch while in 6th

A

57

88

Range verification C3 pressure switch while in N1

C

57

99

Range verification C3 pressure switch while in N2 or N4

C

A.

Active Indicator Clearing Procedure:

Power down

Manual

NOTE:

Before troubleshooting, read Paragraph 56. Also, check battery and ECU input voltages.

NOTE:

Intermittent connections or lack of battery-direct power and ground connections may cause this and

other codes.

B.

Troubleshooting:

1. Disconnect the harness from the transmission. Check the C3 pressure switch circuit at the

feedthrough harness connector for continuity (refer to code 32 XX).

2. Continuity at the feedthrough harness connector indicates the C3 pressure switch is closed or the

C3 circuit is shorted together. Drain the fluid, remove the control module, and isolate the short.

The fault is either a shorted feedthrough harness or stuck C3 pressure switch. Repair or replace as

necessary.

3. If there is no continuity at the transmission, disconnect the transmission harness connector from

the ECU and check the C3 pressure switch wires in the transmission harness for shorts. Use the

system wiring diagram to identify wires which are connected. If a shorted C3 pressure switch cir-

cuit in the external harness is found, isolate and repair.

4. If the C3 pressure switch or circuit is not shorted either in the transmission or the external harness,

connect a pressure gauge in the C3 pressure tap (refer to Appendix B for pressure tap location).

Drive the vehicle in the range indicated by the code or use the diagnostic tool's clutch test mode to

attain that range.

5. If the gauge shows C3 pressure is present in the range indicated by the subcode, drain the fluid and

remove the control module. Check for damaged valve body gaskets or stuck or sticking valves. Re-

pair or replace as necessary. If no obvious defects are found, replace the listed solenoid.

6. If the gauge shows C3 pressure is not present in the range indicated by the subcode, drain the fluid and

remove the control module. Replace the C3 pressure switch.

7. If the condition persists, replace the ECU. If replacing the ECU corrects the problem, reinstall the

original (bad) ECU to confirm that the problem is in the ECU. If the original ECU now works, in-

spect the ECU connectors for any corrosion or damage which may cause an intermittent condition.

If the original problem reoccurs, reinstall the replacement ECU.

0021 00109

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |