|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-2410-237-23

BEVEL GEAR AND SHAFT REPLACEMENT - CONTINUED

0127 00

INSTALLATION - CONTINUED

b.

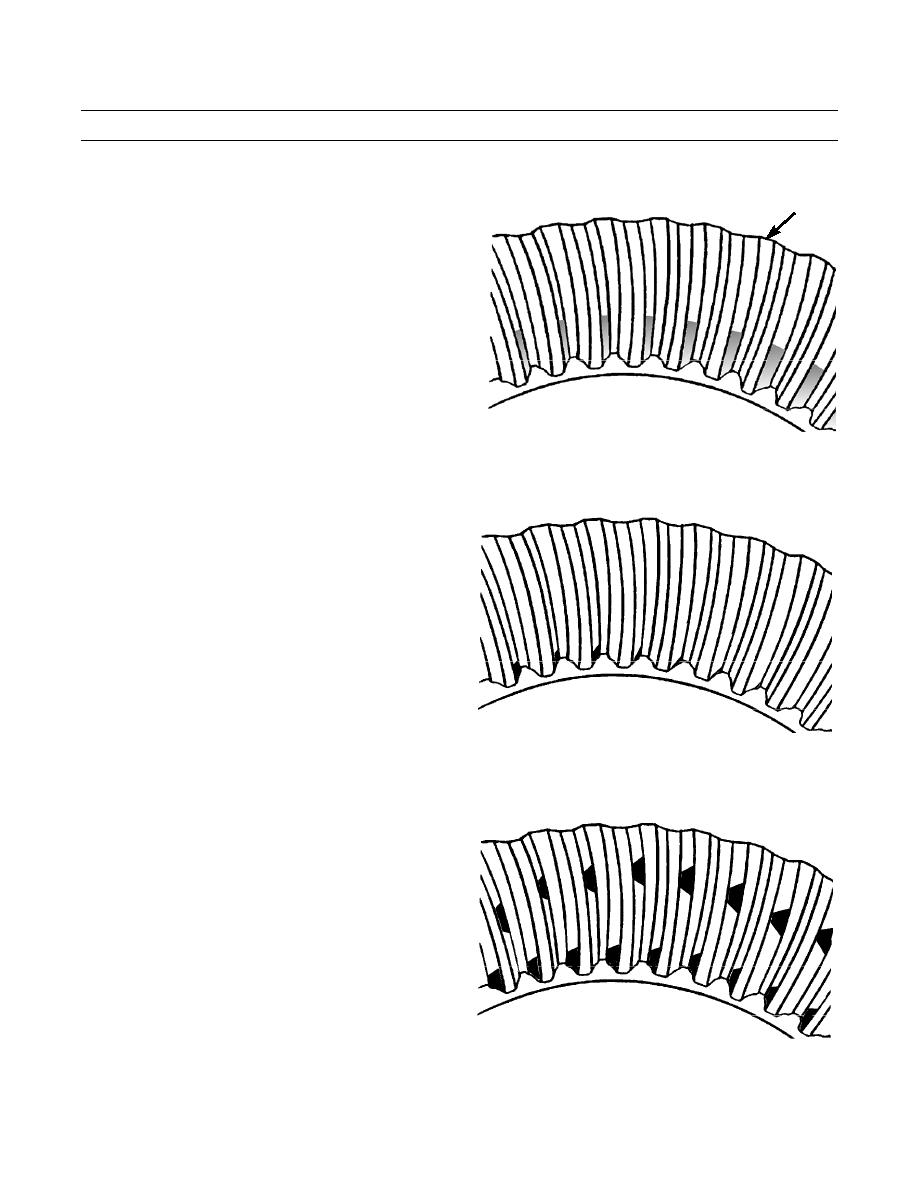

With no load, correct tooth setting will be as

16

shown. The area of contact starts near toe of gear

and goes 30% up length of tooth. With this set-

ting, when load is put on gear it will be over cor-

rect area of teeth.

387-455

c.

If bevel pinion shaft is too far away from bevel

gear, short toe contact will be the result as

shown. The teeth of bevel pinion shaft will be in

contact with toe ends of convex faces (part that

makes a curve toward outside), and top edge of

heel end of concave faces (part that makes a

curve toward inside). To correct this, add shims

between bevel pinion shaft and bearing cage of

transmission. Check gear clearance (backlash)

and tooth contact again.

SHORT TOE CONTACT

387-456

d.

If bevel pinion shaft is too near to center of bevel

gear, short heel contact will be the result as

shown. The teeth of bevel pinion shaft will be in

contact with toe ends of concave faces (part that

makes a curve towards the inside) and the heel

ends of convex faces (part that makes a curve

toward the outside). To correct this, move pinion

shaft away from bevel gear by removal of shims

between bearing cage of transmission and bevel

pinion shaft. After doing this, check gear clear-

ance (backlash) and tooth contact again.

SHORT HEEL CONTACT

387-457

0127 00-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |