|

|||

|

|

|||

|

Page Title:

Carrier Roller Support Assembly |

|

||

| ||||||||||

|

|

NOTE

recoil spring front pilot. Pu1l the cylinder out of the

The torque values for valve (1) and (3) are given in

bore. Packing will come out with the cylinder.

justments as outlined in TM 5-2410-233-20.

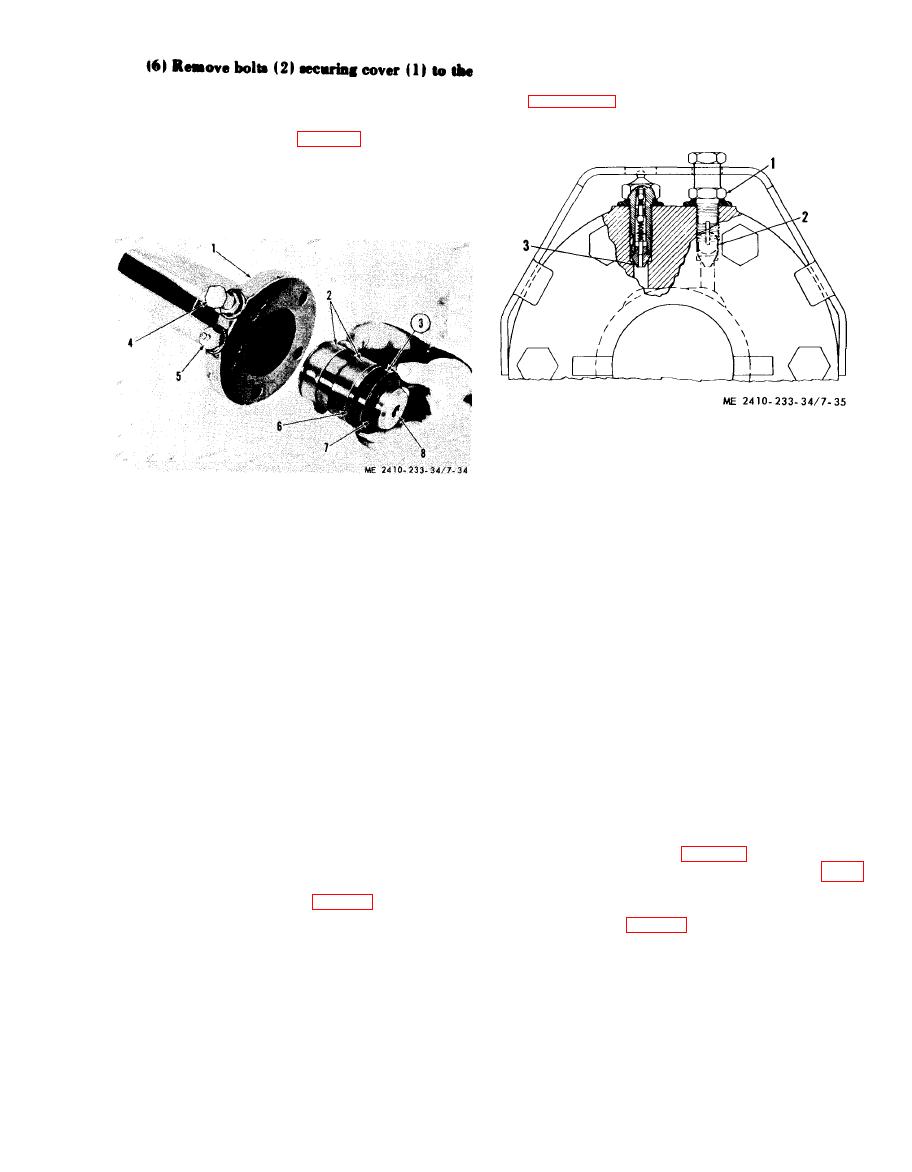

b. Disassembly.

(1) Push piston (8, fig. 7-34) out of cylinder

(1).

(2) Inspect packing (3) and rings (2).

(3) Remove packing (3) and washer (6) after

removing snapring (7).

1 Relief valve

2 Vent hole

3 Fill valve

5 Fill valve

1

Cylinder

6 Washer

2

Rings

7 Snapring

3

Packing

a . Removal.

8 Piston

4

Relief valve

WARNING

Be certain the hydraulic pressure in the

track adjusting mechanism is com-

c. Reassembly.

pletely relieved and the cylinder can be

(1) Install packing with the lip toward

moved to the rear into the recoil spring

snapring (7).

front pilot before attempting to separate

(2) Lubricate the inside of cylinder (1) and

the track or remove the track adjusting

install piston assembly.

mechanism. On tractors that have badly

d. Installation. Install in reverse order of

w o r n track, it is possible for the

removal, rotating the cylinder so the flat (or guard)

hydraulic track adjuster to be adjusted

on the recoil rod flange aligns with the flat on the

forward to the limit of its travel and the

cylinder. Install the adjusting mechanism. Install

stop will be against the equalizer bar

and adjust the track ( e below).

support. The hydraulic cylinder could

e. Track Adjustment.

have high oil pressure in it even though

NOTE

the track is loose enough to remove the

Operate the tracks without excessive tension to

master pin without relieving the

minimize wear. When properly adjusted there should

be 1-inch to 1 inch sag measured at a point half way

hydraulic track adjusting pressure.

between the track carrier roller and front idler.

(1) Remove guards (fig. 7-25).

(1) Raise the inspection plate on the track

(2) Separate the track and iay it out flat (para

roller frame guard.

7-1).

(2) With relief valve (1, fig. 7-35) opened one

(3) Raise the front of the tractor until

turn counterclockwise, force GAA lubricant

equalizer bar (3, fig. 7-36) is against roil bar (2).

through fitting in fill valve (3).

Use blocking to support the front of the tractor.

(3) When the grease coming out vent hole (2)

(4) Remove bolts (4).

front the opened relief valve (1) is thick, close the

(5) Attach a hoist to and remove track carrier

relief valve and continue filling with lubricant until

roller (1, carrier roller bracket (6) and support

the track has 1-inch to 1 inch sag.

assembly (5) as a unit.

(4) Operate the machine backward and for-

ward to equalize the adjustment. Recheek ad-

justment.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |