|

|||

|

|

|||

|

Page Title:

Section Il. HYDRAULIC CONTROL VALVES AND HYDRAULIC PUMP |

|

||

| ||||||||||

|

|

c. Cleaning. Flush and clean inside of hydraulic

tank with cleaning solvent (Fed. Spec. P-D-680).

Wipe outside of tank with a cloth dampened with

cleaning solvent. Wipe dry using a lint-free cloth.

d. Inspection.

( 1 ) Inspect hydraulic tank for cracks, breaks,

dents, broken welds, and corrosion. Tank will be

free of major denta and distortion that will affect

serviceability, capacity or appearance. Replace a

tank that is uneconomical to repair.

(2) Inspect hydraulic tank cap, gasket,

strainer, gage, filter springs, seat, and filter by-pass

v a l v e f o r d a m a g e o r d i s t o r t i o n . R e p l a c e all

defective parts.

e. Repair, Weld minor cracks and broken welds

p e r TM 9-237. Paint welded and other barren

a r e a s per TM 9-213.

f. R e a s s e m b l y a n d I n s t a l l a t i o n . R e v e r s e

disassembly and removal procedure and reassemble

a n d install the hydraulic tank on the tractor.

Replace all damaged gaskets and seals.

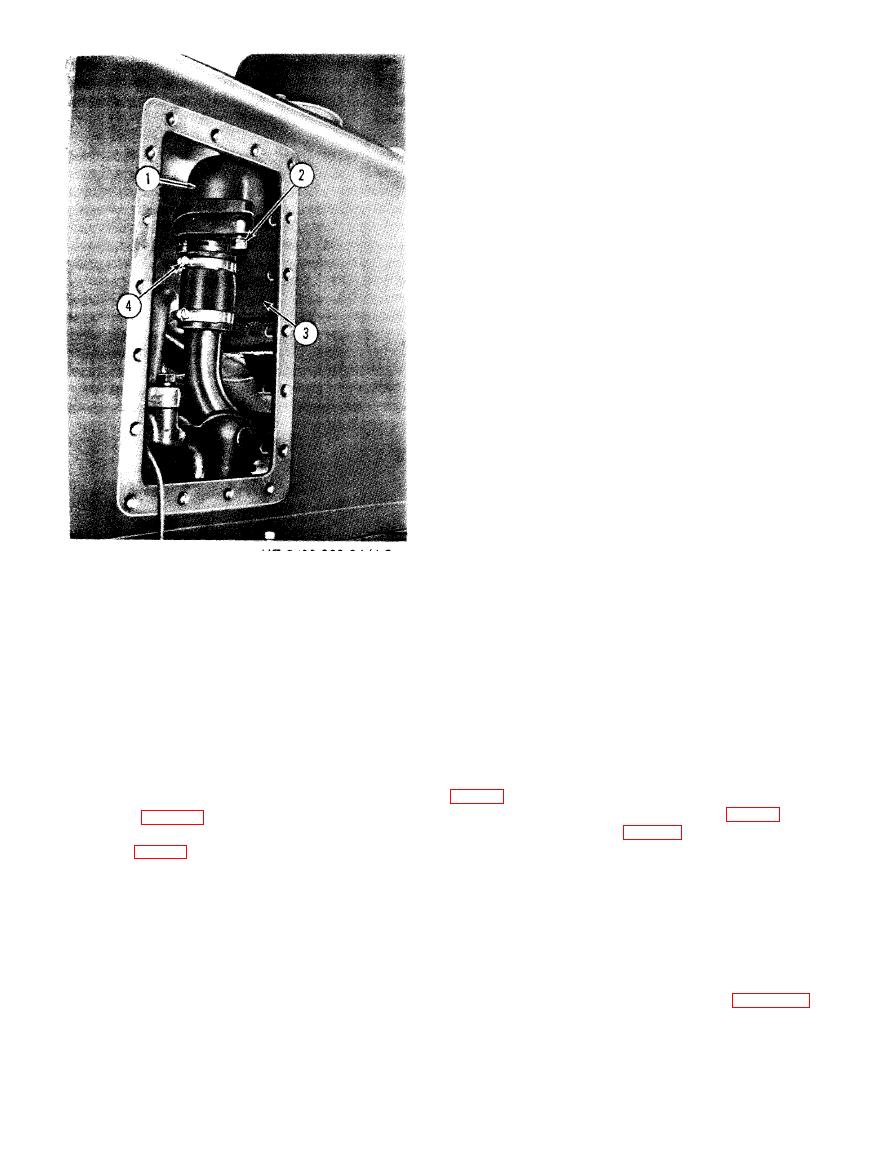

ME 2410-233-34/4-3

1 Filter inlet oil line

2 Bolts

3 Oil filter

4 Hose clamp

Section Il. HYDRAULIC CONTROL VALVES AND HYDRAULIC PUMP

4-3. Bulldozer Control Valve

b. Valve Spool Removal.

(1) Remove and inspect plug assemblies (2,

a. Removal.

(1) Remove the hydraulic control tank from

the end of the plugs engage detent (1, fig. 4-5) to

the tractor (para 4-2).

hold valve spool (4, fig. 4-5) in the FLOAT

(2) Remove the tank a s s e m b l y f r o m b o t t o m

plate ((6), fig. 4-4).

position.

(3) Remove bolts (3 and (14) and remove oil

(2) Remove bolt and lockwasher (5).

line (5).

CAUTION

(4) Disconnect rod (4) from end of control

Valve body (3) and spool (4) are

v a l v e spool-

machined to close tolerances. To avoid

(5) Remove bolt (9 and remove oil line (1).

d i s t o r t i o n of spool (4), leave spool in

( 6 ) Remove bolts (7) and (8) and remove

valve body when loosening or

elbows (10) and (11).

tightening bolt (5).

(7) Remove bolts (12) and remove bulldozer

(4) Disassemble spool as shown in figure 4-6.

c o n t r o l valve (2). The bulldozer control valve

weighs approximately 70 pounds,

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |