|

|||

|

|

|||

|

Page Title:

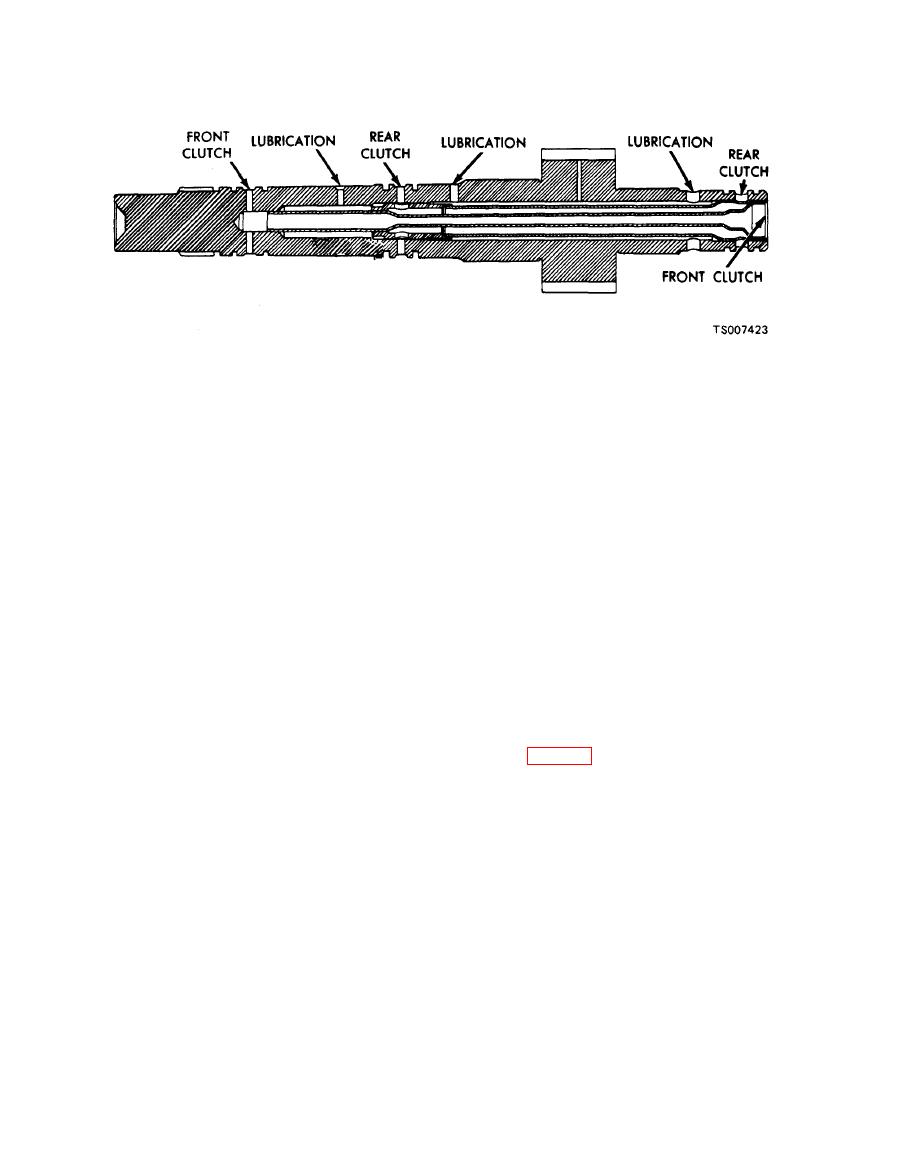

Figure 7-35. Primary Sun Gear Shaft. |

|

||

| ||||||||||

|

|

TM 10-3930-633-34

(4) Inspect the external parking gear teeth

(2) Inspect the sun gear shaft splines for

for damage and the speedometer drive gear teeth

burrs and wear.

for burrs.

(3) Check the fit of the seal rings in the

grooves of the shaft, The rings should enter the

(5) If either the output shaft or ring gear has

been replaced, place the assembled unit with the

grooves freely without bind.

gear face down on the bench, push the shaft

(4) Check the fit of the seal rings in their

downward, and check the clearance between the

respective bores. A clearance of 0.002-0.009 inch

top of the snap ring and its groove. If this

should exist between the ends of the rings.

clearance exceeds 0.002 inch, replace the snap

(5) Install the seal rings on the shaft and

ring wit h a thicker ring to reduce the clearance to

check for free movement in the grooves.

less than 0.002 inch. Selective snap rings are

c. One-way Clutch.

available in several thicknesses for this purpose.

(1) Inspect the outer and inner races for

e. Distributor Sleeve.

scores or damaged surface area where the rollers

(1) Inspect the distributor sleeve for scores or

contact the races. If the outer race is damaged on

excessive ring wear. Inspect the distributor sleeve

the low reverse clutch hub, it must be replaced.

passages for obstructions.

(2) Inspect the rollers and springs for ex-

(2) Check the fit of the fluid tubes in the

cessive wear or damage.

distributors.

(3) Inspect the spring and roller case for bent

f. Planet Carrier and Center Support.

or damaged spring retainers.

(1) Inspect the clutch outer race, inner race,

d. Output Shaft.

(1) Inspect the thrust surfaces and journals

washer (fig. 7-12) for-roughness. -

for scores, Inspect the internal gear for broken or

(2) Inspect the center support bushing for

worn teeth.

roughness.

(2) Inspect the ring grooves for burrs.

(3) Inspect the keyway and drive ball pocket

for wear, and inspect the splines for burrs, twist

or wear.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |