|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

b. Cleaning/Inspection

(1) Clean interior and exterior surfaces of container. Use any process or combination of processes which will

accomplish through cleaning without damage to container.

(2) Clean all desiccant port covers/assemblies removed from container.

(3) Remove paint scale and rust.

(4) Check interior and exterior of container for dents, cracks, defective welds and other defects. Dents

approximately .75 in. (1.9 cm) or less deep that do not penetrate skin or weaken structure are acceptable

and are not considered defects.

(5) Check inner frame for bends and cracks.

(6) Check mounting brackets for bends and cracks.

(7) Check wire basket for defective tack welds.

(8) Check desiccant port covers/assemblies for damage and reusability.

(9) Check vibration dampener mounts for defects, such as cracking, tearing or evidence of separation of

bonding between metal and elastomer, which may affect the function of the mount.

(10) Inspect skids while on container for weakness and wear.

(11) Inspect installation decal for cracks, tears, illegibility and failure of adhesion.

c. Assembly

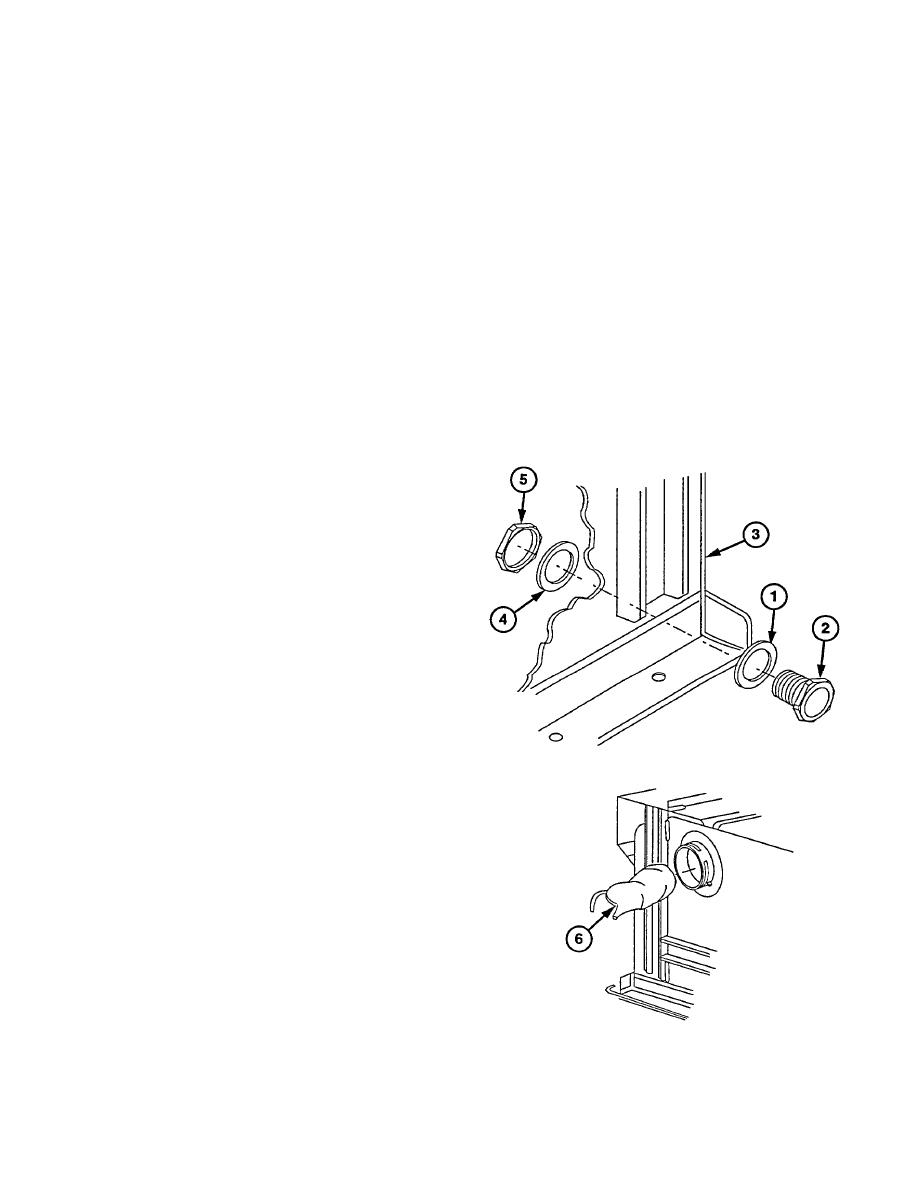

(1) Install gasket (1) and humidity indicator (2)

on upper container (3) with washer (4) and

nut (5).

NOTE

Desiccant comes in bags of eight

units each or 16 units each. The

minimum units for engine is 128

units, transmission and transfer case

is 48 units.

(2) Install appropriate units of desiccant (8 to

16 bags) (6).

Change 1 29-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |