|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

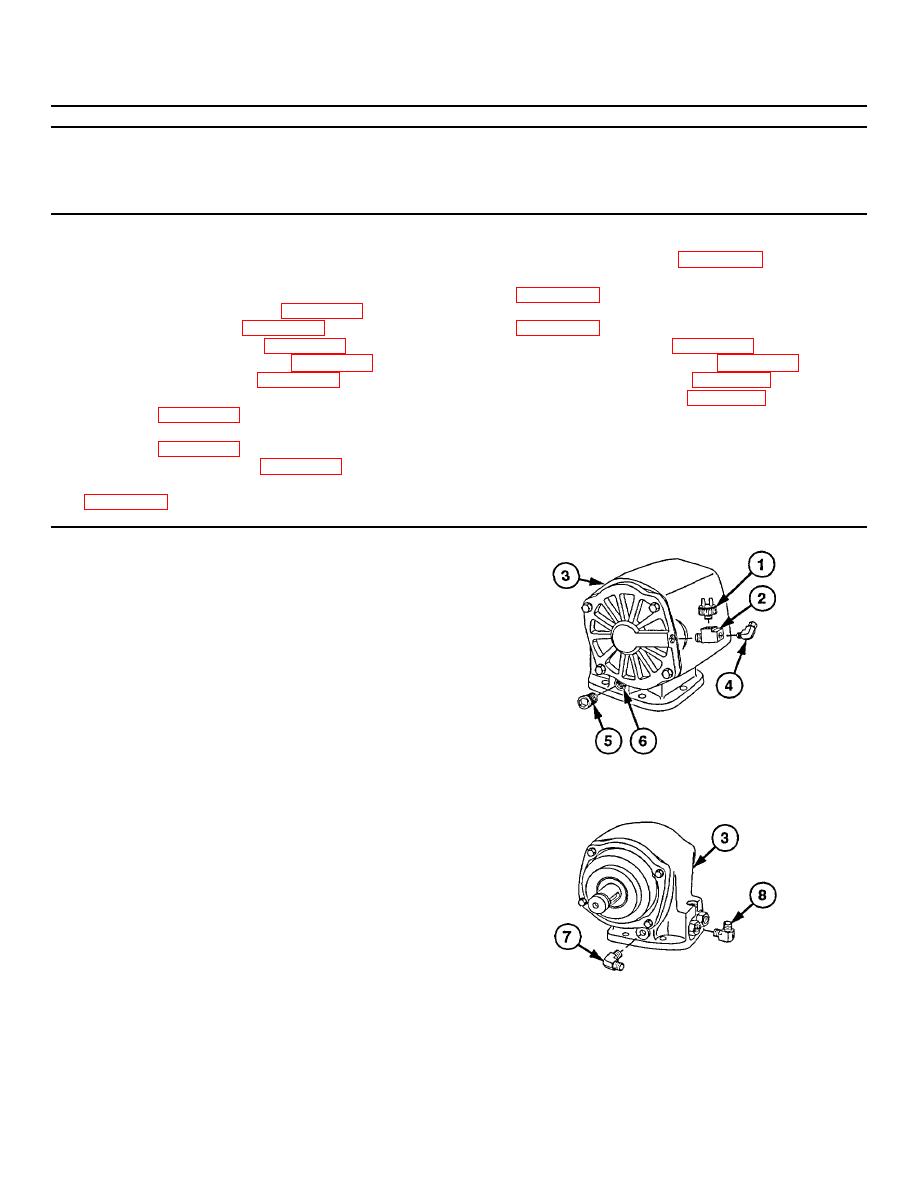

28-6. POWER TAKEOFF REPAIR

This task covers:

a. Disassembly

c. Assembly

b. Cleaning/Inspection

d. Follow-On Maintenance

INITIAL SETUP

Equipment Conditions

Materials/Parts

Power takeoff removed (para 17-12).

Adhesive-Sealant (Item 6, Appendix B)

Compound, Sealing, Pipe Thread (Item 28,

Tools and Special Tools

Tool Kit, Genl Mech (Item 202, Appendix E)

Grease, Automotive and Artillery, (item 32,

Caps, Vise Jaw (Item 17, Appendix E)

Goggles, Industrial (Item 57, Appendix E)

Oil, Lubricating (Item 44, Appendix B)

Pliers, Retaining Ring'(Item 106, Appendix E)

Solvent, Dry Cleaning (Item 54, Appendix B)

Press, Hydraulic (Item 116, Appendix E)

Parts Kit,' Clutch (Item 208, Appendix F)

Puller Kit, Mechanical, Gear and Brg

Parts Kit, Linear (Item 210, Appendix F)

(Item 124, Appendix E)

Socket, Sockethead Screw, 1/8 In,

(Item 170, App endix E)

Vise, Machinist's (Item 207, Appendix E)

Wrench, Torque, 0-300 Lb-In. (Item 235,

a. Disassembly

(1) Remove switch (1) from reducer (2).

(2) Remove reducer (2) from power takeoff

(PTO) housing (3). Discard preformed

packings.

(3) Remove elbow (4) from reducer (2).

(4) Remove plug (5) from idler shaft (6).

(5) Remove elbows (7 and 8) from PTO

housing (3).

28-61

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |