|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

28-5. AUXILIARY WINCH REPAIR

This task covers:

a. Disassembly

c.

Assembly

b. Cleaning/Inspection

INITIAL SETUP

Equipment Conditions

Materials/ Parts

Auxiliary winch on clean work surface.

Compound, Sealing, Pipe Thread (Item 28,

Solvent, Dry Cleaning (Item 54, Appendix B)

Tools and Special Tools

Tool Kit, Genl Mech (Item 202, Appendix E)

Lockwashers (6) (Item 119, Appendix F)

Caliper Set, Micrometer (Item 15, Appendix E)

Lockwashers (7) (Item 122, Appendix F)

Compressor Unit, Air (Item 24, Appendix E)

Lockwasher (1) (Item 111, Appendix F)

Gage Set, Telescoping (Item 56, Appendix E)

Lockwasher (Item 118, Appendix F)

Goggles, Industrial (Item 57, Appendix E)

Lockwasher (Item 120, Appendix F)

Pan, Oil Drain (Item 102, Appendix E)

Repair Kit, Winch (Item 232, Appendix F)

Press, Hydraulic (Item 116, Appendix E)

Service Kit, Winch (Item 321, Appendix F)

Socket, Sockethead Screw, 3/16 In.

(Item 172, Appendix E)

Wrench, Torque, 0-300 Lb-In. (Item 235,

Wrench, Torque, 0-175 Lb-Ft (item 236,

a. Disassembly

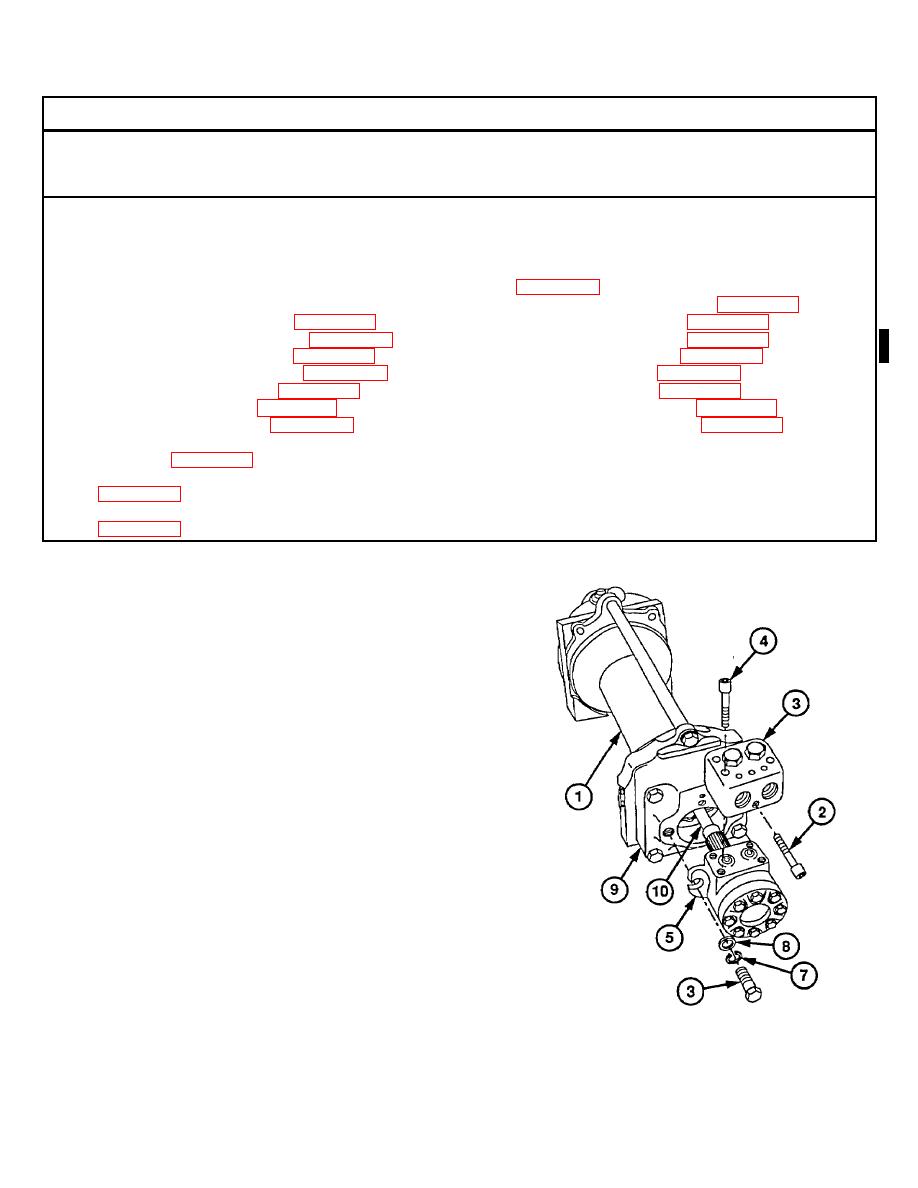

(1) Place auxiliary winch (1) on clean work surface.

(2) Remove screw (2) from counterbalance valve

(3).

(3) Remove four screws (4) and counterbalance

valve (3) from auxiliary winch drive motor (5).

(4) Remove two screws (6), lockwashers (7), and

washers (8) from brake housing assembly (9).

Discard lockwashers.

(5) Remove auxiliary winch drive motor (5) with

input shaft (10) from brake housing assembly

(9).

28-49

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |