|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

28-2. WINCH REPAIR

This task covers:

a. Disassembly

c. Assembly

b. Cleaning/Inspection

d. Follow-On Maintenance

INITIAL SETUP

Equipment Conditions

Materials/Parts

Winch drained of lubricant

Adhesive-Sealant, Silicone (Item 2, Appendix B)

(TM 9-2320-360-20).

Adhesive-Sealant (Item 10.1, Appendix B)

Compound Sealing, Pipe Thread (Item 28,

Tools and Speci al Tools

Tool Kit, Genl Mech (Item 202, Appendix E)

Oil, Lubricating (Item 41, Appendix B)

Compressor Unit, Air (Item 24, Appendix E)

Solvent, Dry Cleaning (Item 54, Appendix B)

Goggles, Industrial (Item 57, Appendix E)

Brake Seal Kit (item 297, Appendix F)

Press, Hydraulic (Item 116, Appendix E)

Locknuts (2) (Item 93, Appendix F)

Pliers, Retaining Ring (Item 107, Appendix E)

Lockwashers (31) (Item 120, Appendix F)

Rods, Threaded (2) (Figure C-14, Appendix C)

Lockwashers (18) (Item 124, Appendix F)

Screws, Guide (2) (Figure C-4, Appendix C)

Lockwashers (6) (Item 121, Appendix F)

Sling Assemblies (2) (Item 160, Appendix E)

Lockwashers (2) (Item 122, Appendix F)

Sling, Endless Strap (Item 161, Appendix E)

Lockwashers (2 ) (item 129, Appendix F)

Wrench, Torque, 0-300 Lb-in. (Item 235,

Lockwashers (2) (Item 130, Appendix F)

Service Kit, Winch (Item 231, Appendix F)

Wrench, Torque, 0-175 Lb-Ft (Item 236,

Personnel Required

Two

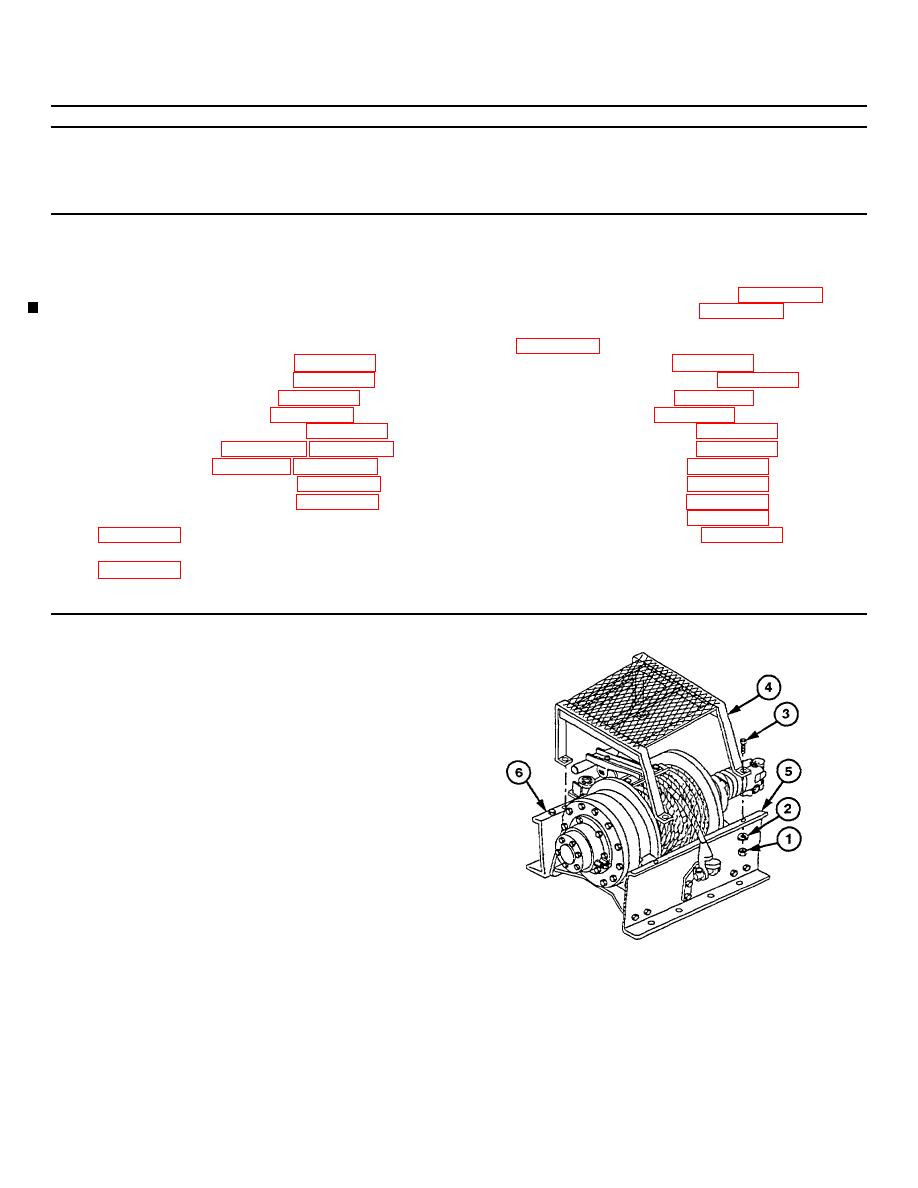

a. Disassembly

(1) Remove four nuts (1), lockwashers (2),

screws (3), and cable guard (4) from

winch side supports (5 and 6). Discard

28-2 Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |