|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-34-2

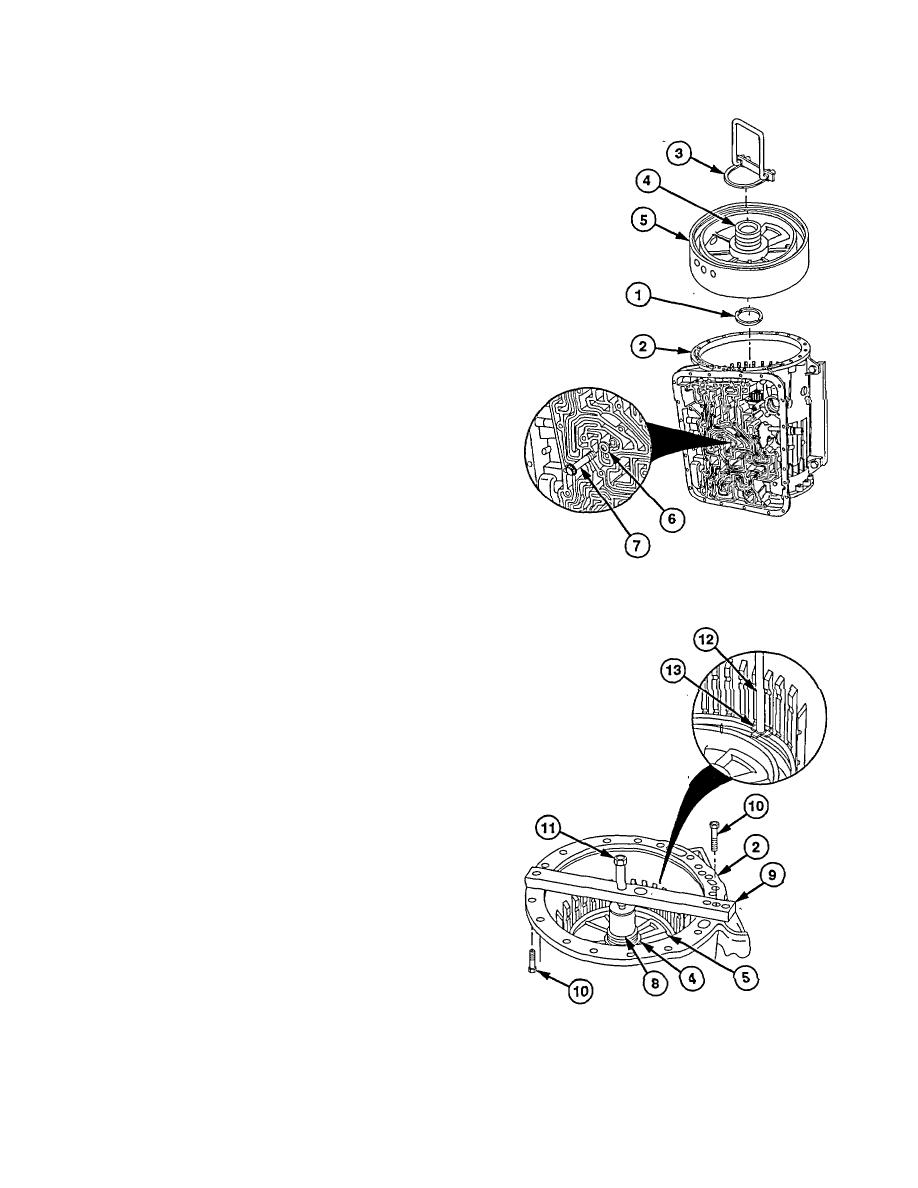

e. Installation

(1) Install thrust washer (1) in transmission

(2).

(2) Install lifting bracket (3) on center support

hub (4).

NOTE

Ensure tapped hole on center

support housing is aligned with hole

in transmission housing.

(3) Lower center support (5) into transmission

(2).

(4) Position washer (6) and anchor screw (7)

in transmission (2) and center support (5).

Do not tighten.

(5) Remove lifting bracket (3) from center

support hub J4).

(6) Install compressor sleeve (8) on hub (4) of

center support (5). Place compressor bar

(9) across transmission (2). install two

screws (10).

(7) Tighten compressor screw (11) to 60 lb-in.

(6.8 N m) to compress center support (5).

(8) Using retaining ring gage (12), measure

retaining ring opening with each of four

lugs (13). This will determine retaining

ring size.

(a) Blue color-coded ring is 0.1480.150

in. (3.76 to 3.81 mm thick).

(b) Yellow

color-coded

ring

is

0.1520.154 in. (3.86-3.91 mm) thick.

(c) White

color-coded

ring

is

0.1550.157 in. (3.94-3.99 mm) thick.

(d) Red color-coded ring is 0.1580.160

in. (4.01-4.06 mm) thick.

22-81

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |