|

|||

|

|

|||

|

Page Title:

ENGINE BLOCK REPAIR (CONT) |

|

||

| ||||||||||

|

|

TM 9-2320-360-34-2

19-4. ENGINE BLOCK REPAIR (CONT)

b. Cleaning/lnspection

(1) Scrape gasket material and sealant from engine

block surfaces.

WARNING

High pressure steam may blow

particles Into eyes, may cause severe

bums, and creates hazardous noise

levels.

Eye, skin, and hearing

protection Is required to prevent

Injury to personnel.

NOTE

Oil and water galleries in engine

block must be thoroughly steam

cleaned.

(2) Steam de an engine block.

WARNING

Compressed

air

for

cleaning

purposes will not exceed 30 psi (207

kPa). Use only with effective chip

guarding and personal protective

equipment (goggles/shield, gloves,

etc.).

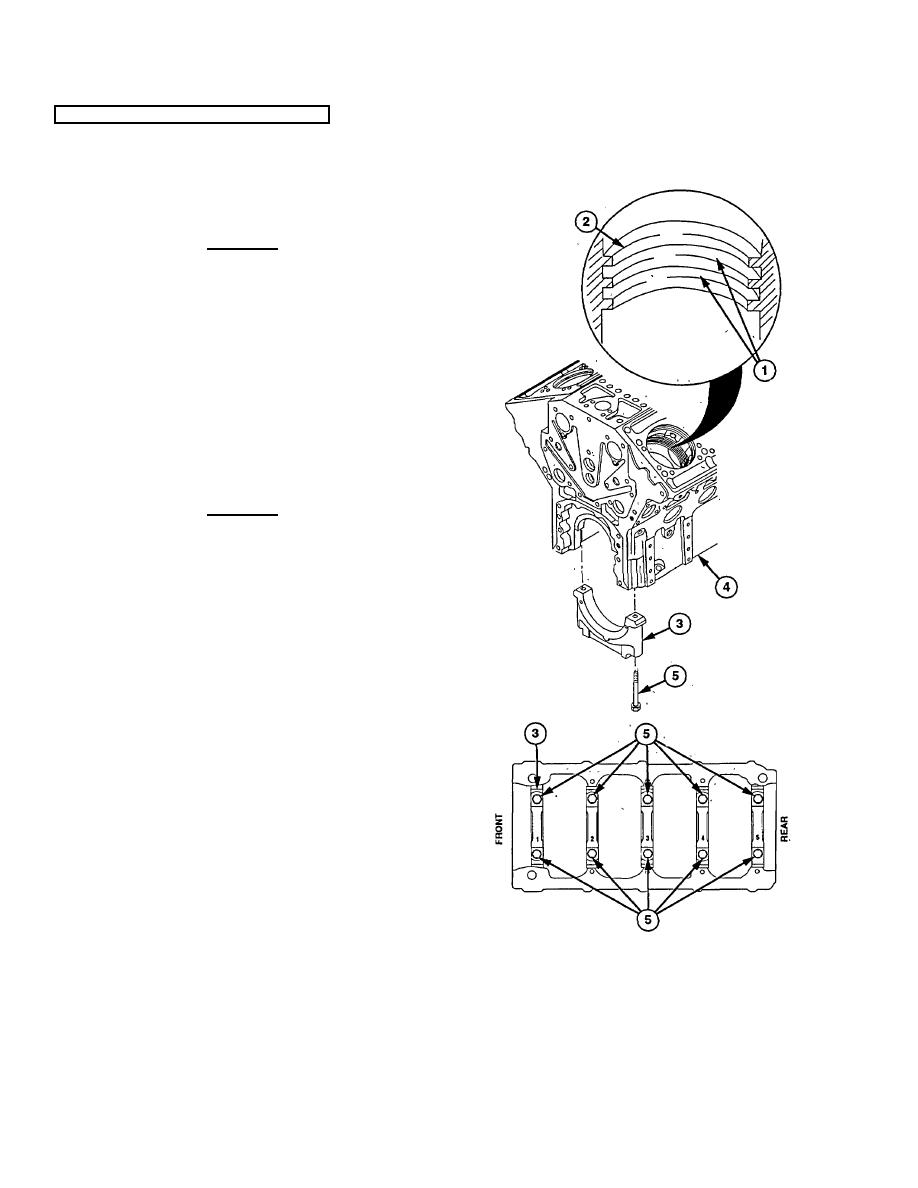

(4) Inspect grooves (1) and lands (2) for pitting and

erosion.

NOTE

Main bearing caps must be installed

in proper positions in engine block

as marked during removal (para 19-

8). Ensure caps are firmly seated in

engine block and that main bearing

shells are removed.

(5) Install 5 main bearing caps (3) in bottom of

engine block (4) with 10 screws (5). Torque to

20 lb-in. (2.3 N-m).

(6) Seat caps (3) by striking with soft-faced

hammer.

(7) Tighten screws (5) to 50 lb-ft (68 N-m), then to

110 lb-ft (149 N-m), and then to 250 Ib-ft (339 N-

m).

19-14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |