|

| |

TM 9-2320-360-34-1

NOTE

· One revolution of the winch

drum

every

16

seconds

approximately equals the rated

line speed of 13 feet/minute.

· All tests within this fault must

be preformed with main winch

cable connected to a load.

Another

M1070

tractor,

or

equivalent, can be used for this

purpose.

· Winch hydraulic reservoir filter

should be at least warm to the

touch and engine on high idle

during troubleshooting.

WINCH OPERATION TEST

(1) Operate faulty main winch

(TM 9-2320-360-10).

(2) Pay out enough cable so that the winch

cable is down to the third layer.

(3) Attach winch cable to load.

(4) Mark starting position on winch drum.

(5) Set WINCH SPEED CONTROL to

LOW position (TM 9-2320-360-10).

(6) Push down winch control lever and

record the time required to make one

drum revolution.

(7) Shut off engine (TM 9-2320-360-10).

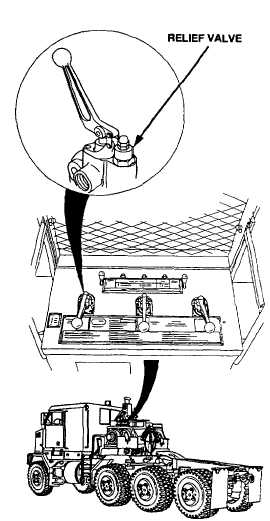

WINCH CONTROL VALVE TEST

WARNING

· Never switch relief valves between the

main winch control valves and the

auxiliary winch control valve. The

pressure settings are different between

the main and auxiliary winches.

· Relief valve pressure settings are

factory preset and should not be

adjusted. Never attempt to adjust the

relief valve setting. Failure to comply

may result in injury to personnel.

CAUTION

Use extra care when removing relief valves

from control valves. Failure to comply may

result in damage to relief valve or control

valve.

(1) Switch relief valves between the two main winch

control valves.

(2) Operate faulty main winch (TM 9-2320-360-10).

(3) Push down winch control lever and record the time

required to make one drum revolution.

(4) Shut off engine (Tm 9-2320-360-10).

(5) Switch relief valves back to their original positions.

Change 1 2-185.3

|