|

| |

TM 9-2320-360-34-1

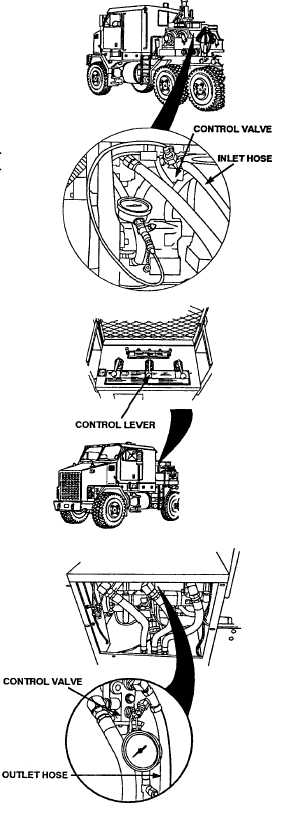

HYDRAULIC SYSTEM TEST

WARNING

Never disconnect any hydraulic hose while

engine is running. Allow several minutes before

shutting engine off for pressure to drop

NOTE

· Winch testing should be done with 10 ft (3 m)

of cable payed out.

· Winch hydraulic reservoir filter should be at

least warm to the touch and engine on high

idle during troubleshooting.

· Winch hydraulic pump contains three

separate sections.

(1) Remove winch console panels (TM 9-2320-360-20).

(2) Remove inlet hose from control valve.

(3) Install tee, pressure gage and pressure hose on control

valve.

(4) Disengage auxiliary winch kickout (TM 9-2320-360-10).

(5) Start engine and engage PTO and high idle

(TM 9-2320-360-10).

(6) Pull up or push down control valve lever, and observe

pressure.

(7) Disengage high idle and PTO and shut engine off

(TM 9-2320-360-10).

(8) Remove pressure hose, pressure gage and tee from

control valve.

(9) Install inlet hose on control valve.

HYDRAULIC SYSTEM TEST

(1) Remove outlet hose from control valve.

(2) Install tee, pressure gage and pressure

hose on control valve.

(3) Start engine (TM 9-2320-360-10).

(4) Pull up and hold winch control lever

while observing pressure.

(5) Release winch control lever and shut

engine off (TM 9-2320-360-10).

(6) Remove pressure hose, pressure gage

and tee from control valve.

(7) Install outlet hose on control valve.

Change 1 2-185.1

|