|

| |

TM 9-2320-360-34-1

WARNING

Never disconnect any hydraulic hose while engine is

running. Allow several minutes after shutdown for

engine pressure to drop.

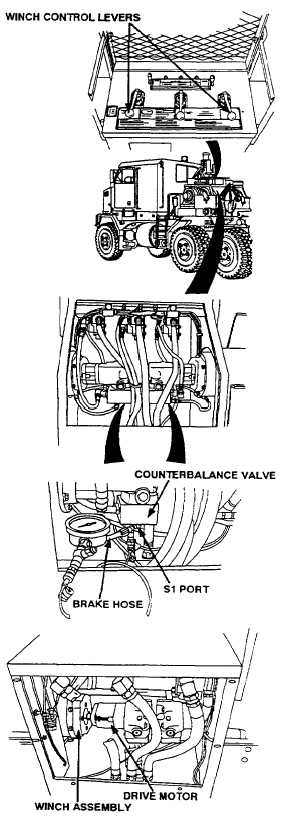

HYDRAULIC SYSTEM TEST

NOTE

· Winch testing should be done with 10 ft (3 m)

of cable payed out and no load on cable.

· Winch hydraulic reservoir filter should be at

least warm to the touch and engine on high

idle during troubleshooting.

(1) Remove brake hose from S1 port on counterbalance

valve.

(2) Install tee, pressure gage and pressure hose on

counterbalance valve.

(3) Start engine, engage PTO and high idle

(TM 9-2320-360-10).

(4) Pull up or push down winch control lever and observe

pressure.

(5) Release winch control lever, disengage high idle and PTO,

and shut off engine (TM 9-2320-360-10).

(6) Remove pressure hose, pressure gage and tee from

counterbalance valve.

(7) Remove brake hose from hydraulic systems tester.

(8) Install brake hose on S1 port of counterbalance valve.

DRIVE MOTOR TEST

NOTE

· Winch hydraulic reservoir should beat

least warm to the touch and engine on

high idle during winch troubleshooting

· Winch assembly will leak gear oil when

drive motor is removed.

(1) Remove two screws, lockwashers and drive motor

from winch assembly with aid of assistant

(2) Start engine and engage PTO and high idle

(TM 9-2320-360-10).

(3) Operate winch drive motor by pulling up and pushing

down on control lever while assistant supports motor.

(4) Disengage high idle and PTO and shut off engine

(TM 9-2320-360-10).

NOTE

If results of troubleshooting indicate faulty

winch drive motor, do not do step (5)

(5) Install drive motor on winch assembly with two new

lockwashers and screws with aid of assistant

2-185

|