|

| |

TM 9-2320-360-34-1

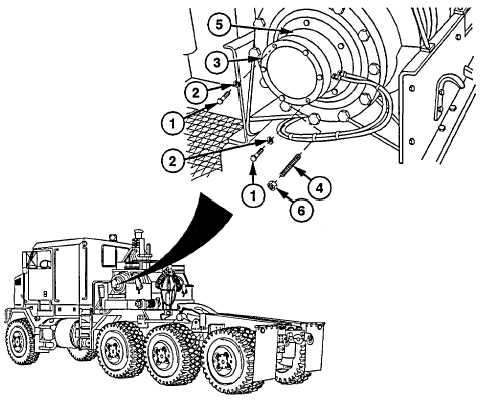

17-10. KICKOUT PISTON AND SEALS REPAIR

This task covers:

a. Disassembly

c.

Assembly

b. Cleaning/Inspection

d.

Follow-On Maintenance

INITIAL SETUP

Equipment Conditions

Materials/Parts

Engine shut off (TM 9-2320-360-10).

Adhesive-Sealant, Silicone (Item 2,

Parking brake on (TM 9-2320-360-10).

Appendix B)

Wheels chocked.

Compound, Sealing, Pipe Thread (Item 28,

Winch drained of lubricant

Appendix B)

(LO 9-2320-360-12).

Solvent, Dry Cleaning (Item 54, Appendix B)

Lockwashers (12) (Item 120, Appendix F)

Tools and Special Tools

Packings, Preformed (2) (Item 196, Appendix F)

Tool Kit, Genl Mech (Item 202, Appendix E)

Packing, Preformed (Item 197, Appendix F)

Compressor Unit, Air (Item 24, Appendix E)

Packing, Preformed (Item 200, Appendix F)

Goggles, Industrial (Item 57, Appendix E)

Ring, Retaining (Item 239, Appendix F)

Pliers, Retaining Ring (Item 107, Appendix E)

Rods, Threaded (2) (Figure C-14, Appendix C)

Wrench, Torque, 0-300 Lb-in. (Item 235,

Appendix E)

Wrench, Torque, 0-175 Lb-Ft (Item 236,

Appendix E)

a.

Disassembly

NOTE

Right and left sides are disassembled

the same way. Left side is shown.

(1)

Remove two opposite screws (1) and

lockwashers (2) from clutch end cover (3).

Discard lockwashers.

(2)

Install two threaded rods (4) in clutch

adapter (5).

(3)

Install two nuts (6) on threaded rods (4).

Tighten nuts until they contact clutch end

cover (3).

17-30

|