|

| |

TM 9-2320-360-34-1

15-5. REAR SUSPENSION ARM REPLACEMENT

This task covers:

a. Removal

c. Follow-On Maintenance

b. Installation

INITIAL SETUP

Equipment Conditions

Materials/Parts

Wheel/tire removed (TM 9-2320-360-20).

Adhesive-Sealant (Item 8, Appendix B)

Air system drained (TM 9-2320-360-10).

Beam Hanger Bolt Kit (Item 3, Appendix F)

Shock absorbers removed (axle no. 2 and

Bushing Bolt Kit (Item 4, Appendix F)

axle no. 3 only) (TM 9-2320-360-20).

Lockwashers (4) (Item 132, Appendix F)

Tools and Special Tools

Personnel Required

Tool Kit, Genl Mech (Item 202, Appendix E)

Two

Jack, Floor (Item 90, Appendix E)

Jackstand (Item 93, Appendix E)

Multiplier, Torque, 4000 lb-ft (Item 99,

Appendix E)

Wrench, Combination, 1-1/2 In. (Item 214,

Appendix E)

Wrench, Open-End, 1-7/8 & 1-11/16 In.

(Item 225, Appendix E)

Wrench Set, Socket, 3/4 In. Drive (Item 231,

Appendix E)

Wrench, Torque, 0-600 Lb-Ft (Item 233,

Appendix E)

a. Removal

WARNING

Do not work on any Item supported

only by Jack or hoist. Always use

jackstands or blocks to support any

Item prior to work. Equipment may

fall and cause Injury or death.

NOTE

· Right and left suspension arms are

replaced the same way. Right side is

shown.

· Axle should be level side to side for

easier removal.

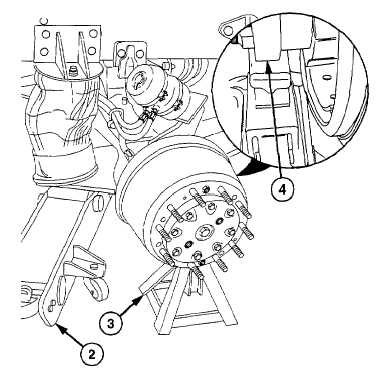

(1)

Lift axle housing (1) with jack (2) and support

with jackstand (3) at axle flange (4). Remove

floor jack (2).

15-18

|