|

| |

TM 9-2320-360-20-1

WARNING

·

Exercise extreme caution when working around wheels or under truck while engine is

running. Movement of truck may cause severe Injury or death.

Wear safety goggles when performing leakage tests on valves air hoses. Failure to

comply may cause serious eye Injury due to high air pressure.

NOTE

·

The CTI system initially and periodically checks for system air leaks. The CTIS will display a

flashing LOW AIR light and shut off if 6 psi cannot be maintained by the CTI system . The

manifold will click during this test for approximately 1.5 minutes.

·

Excessive inflation times (without low air light) are caused by minor leaks in CTI system

·

CTIS air lines are pressurized only when CTIS is in inflate, deflate, or test cycles.

·

Tests 1 thru 5 can be made consecutively while the CTI system is in the inflate cycle

·

Normal inflation time from EMERGENCY to HIGHWAY setting is approximately 12 minutes at

high idle

·

Excess inflation times, sometimes accompanied by a LOW AIR light is normal If engine is at

Idle RPM and/or air operated accessories are being used

·

Soap solution may be used to detect air leaks.

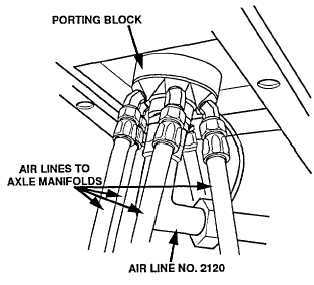

With engine shut OFF, listen for air leaking

from exhaust port (hose no 2120)

POWER MANIFOLD PRESSURE

TEST

(1)

Remove transducer from power manifold

(para 7-67).

(2)

Set CTIS to HIGHWAY setting

(TM 9-2320-360-10).

(3)

Start engine (TM 9-2320-360-10).

(4)

Move CTIS switch to ON position and/or

press START button (TM 9-2320360-10)

(5)

Check for any air pressure at transducer

port on power manifold

(6)

Shut off engine (TM 9-2320-360-10).

(7)

Install transducer in power manifold

(para 7-67).

NOTE

Tire must be deflated to

60 psi (414 kPa) or less

to perform this test

(1)

Start engine (TM 9-2320-360-10).

(2)

Set CTIS controller selector to

HIGHWAY position

(TM 9-2320-360-10).

(3)

Move CTIS switch to ON position and/or

push start button (TM 9-2320-360-10).

(4)

Check air lines from the porting block to

the axle manifolds for air leaks.

(5)

Shut off engine (TM 9-2320-360-10).

Change 1 2-843

|