|

| |

TM 9-2320-360-20-1

AIR COMPRESSOR TEST

(1)

Drain air system (TM 9-2320-360-10)

(2)

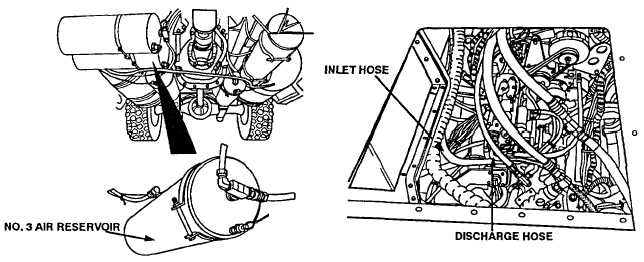

Remove drain plug from no. 3 air tank.

WARNING

Air compressor discharge hose no. 2001 gets extremely hot during normal

air compressor operation. Allow sufficient time for hose to cool before

performing inspection. Failure to comply may result in injury to personnel.

(3)

Remove air compressor discharge hose no. 2001 and inlet hose no. 2600 from air compressor.

(4)

Start engine (TM 9-2320-360-10)

(5)

Operate engine at 2100 RPM for five minutes to bring air compressor up to operating temperature.

(6)

Reduce engine speed to 1800 RPM and maintain that speed.

WARNING

Use extreme care while holding cardboard when engine is running. Rotating

engine accessories and hot engine parts may cause injury.

(7)

Hold a 5 in x 10 in. (12 7 cm x 25 4 cm)piece of cardboard 1 in. (2.54 cm) from the discharge port

for 1 minute

(8)

Shut off engine (TM 9-2320-360-10).

(9)

Compare cardboard to the following

a. No oil spot- compressor OK

b. Oil spot 2 in (5 cm) or less, splatter off to one side, or light splatter - compressor OK

c. Oil spot greater than 2 in. (5 cm) and/or heavy splatter - compressor faulty

(10) lnstall air compressor discharge hose no. 2001 and inlet hose no. 2600 on air compressor.

WARNING

Pipe thread sealing compound can burn easily, can give off harmful vapors,

and is harmful to skin and clothing. To avoid injury or death, keep

compound away from open fire and use in well-ventilated area. If pipe

thread sealing compound gets on skin or clothing, wash immediately with

soap and water.

CAUTION

Use pipe thread sealing compound sparingly, only on pipe threads. Do not apply

compound at hose connections. Failure to comply may result in component

damage

(11) Coat threads of drain plug with pipe thread sealing compound

(12) lnstall drain plug in no. 3 air tank.

2-771.2

|