|

| |

TM 9-2320-360-20-1

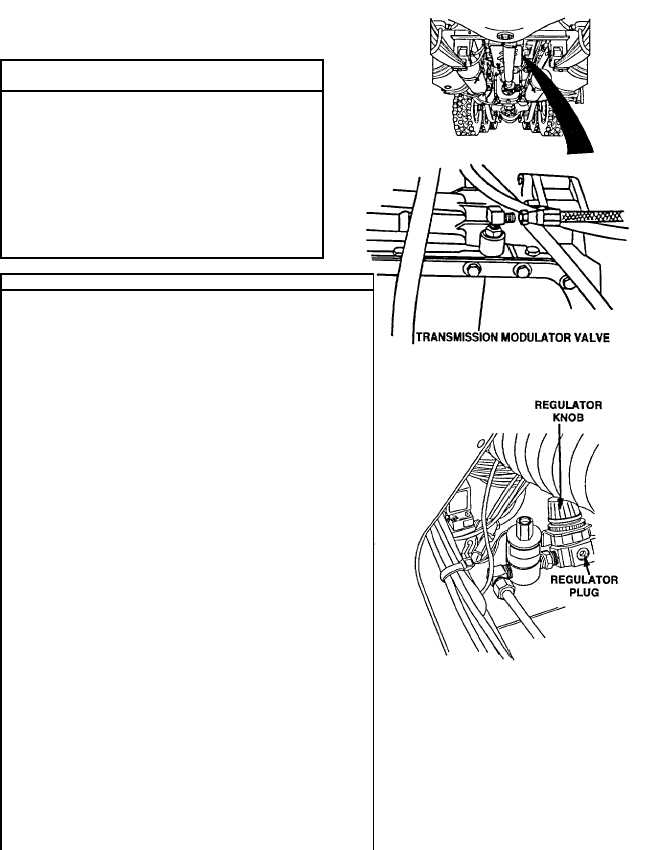

TRANSMISSION MODULATOR VALVE

TEST

(1)

Remove air line no. 2857 from transmission

modulator valve.

(2)

Inspect for external transmission fluid leaks and

presence of transmission fluid inside air line no.

2857.

(3)

Remove transmission modulator valve (para

8-9).

(4)

Apply air pressure to air line fitting Center

plunger should move out when air pressure is

applied.

(5)

Install transmission modulator valve (para 8-9).

PRESSURE TEST

(1)

Remove plug from regulator.

(2)

Install adapter and STE/ICE transducer on regulator.

(3)

Start engine (TM 9-2320-360-10) and allow air system

pressure to build up to 120-125 psi (827-862 kPa).

(4)

Shut off engine (TM 9-2320-360-10).

(5)

Perform STE/ICE test #50 and observe pressure

displayed.

(6)

Pull regulator knob to unlock air pressure regulator.

(7)

Adjust air pressure regulator to proper air pressure using

STE/ICE Test #50. Turn knob clock wise to increase

pressure or counterclockwise to decrease pressure.

(8)

Push in knob to lock air pressure regulator.

(9)

Drain air system (TM 9-2320-360-10).

(10) Remove adapter and STE/ICE transducer from regulator.

WARNING

Pipe thread sealing compound can

burn easily, can give off harmful

vapors, and is harmful to skin and

clothing. To avoid Injury or death, keep

compound away from open fire and use

in well-ventilated area. If pipe thread

sealing compound gets on skin or

clothing, wash Immediately with soap

and water.

CAUTION

Use pipe thread sealing compound

sparingly, only on pipe threads. Do not

apply compound at hose connections.

Failure to comply may result in component

damage.

(11) Coat threads of plug with pipe thread sealing compound.

(12) lnstall plug on regulator.

(13) lnstall dash access panel on dash with 13 screws.

Change 1 2-651

|