|

| |

TM 9-2320-360-20-1

CAUTION

Use jumper wire only between terminals

indicated. Failure to comply may result in

damage to DDEC components or wiring.

NOTE

·

The following chart should be used only

if DDEC troubleshooting was started on

pg. 2-80 and you were referred here.

·

A false DDEC historical Code 14 may be

logged during cold starts in extremely

cold environments, -50 to -26F° (-46 to -

32° C). Typically, the CHECK ENGINE

light will come on 8 minutes after starting

and go out 2-3 minutes later. If the

vehicle has been operated under these

conditions, clear the historical codes and

return the vehicle to service.

(1)

Turn ENGINE switch OFF.

(2)

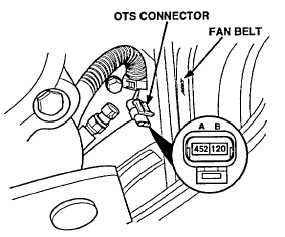

Disconnect OTS and install a jumper between OTS

connector sockets A and B.

(2.1) Click on 'Alarms Clear" to clear alarms screen.

(3)

Turn ENGINE switch ON and read active codes.

WARNING

·

Batteries must be disconnected before

tightening any connections. Failure to

comply may result in injury to personnel.

·

Remove all jewelry such as rings, dog

tags, bracelets, etc. If jewelry contacts

electrical terminals a direct short may

result in an instant heating of tools,

damage to equipment, and injury to

personnel.

CONTINUITY TEST

(1)

Turn ENGINE switch OFF and remove jumper.

(2)

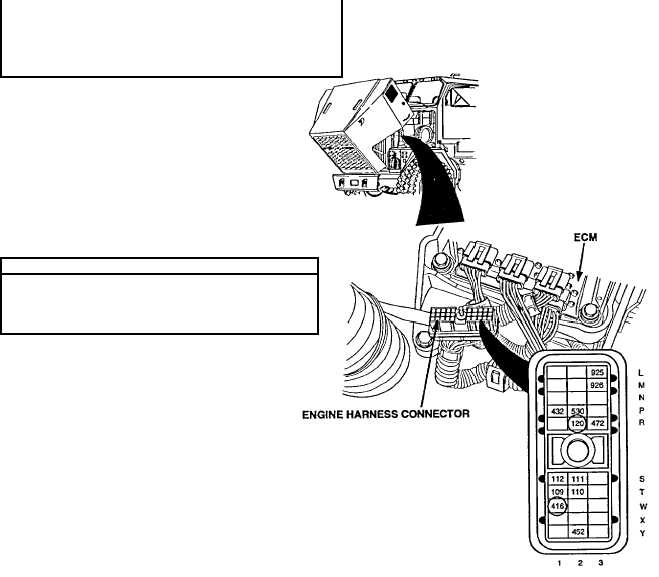

Disconnect engine harness connector at ECM.

(3)

Read resistance between sockets R2 and W1

on engine harness connector.

Inspect OTS and terminals at OTS connectors (both sensor

and harness sides) for damage; bent, corroded, and

unseated pins or sockets

Change 2 2-127

|