|

| |

TM 9-2320-356-BD

5.

Repair using one of the following:

a. Apply fiberglass following kit instructions.

b.

Mix and apply epoxy following kit instructions.

c.

Cut patch material, drill tank and patch, and coat patch liberally with

fuel-resistant gasket sealer.

Attach patch, and secure with pop-rivets. Seal

rivet heads with sealer.

6.

Install fuel tank, if removed.

7.

Record the BDAR action taken.

When the mission is completed, as soon as

practicable, repair using standard maintenance procedures.

Option 3:

Plug Holes (Metal or Fiberglass Tanks).

Limitations:

o None

Personnel/Time Required:

o 1-3 soldiers

o 1-3 hours

Materials/Tools:

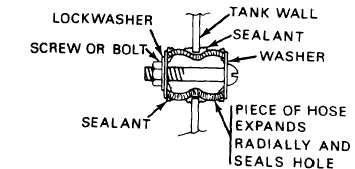

o Rubber hose

o Bolt and nut

o Two large flat washers

Other Options:

o Use fiberglass or epoxy.

Procedural Steps:

1.

Drain fuel until level is below the

hole.

2.

If removal of the fuel tank is

necessary, drain tank.

3.

Obtain hose the approximate size of

the hole.

4.

Assemble the hose, bolt, nut, and

washers as shown.

5.

Coat the hose assembly with sealer

to aid in the repair.

6.

Insert the hose assembly into the hole.

7.

Tighten the bolt and nut to make the hose expand and seal the fuel tank hole.

8.

Install the fuel tank, if removed.

9.

Record the DAR action taken.

When the mission is completed, as soon as

practicable, repair using standard maintenance procedures.

6-5

|