|

| |

TM 9-2320-356-BD

Section X.

HYDRAULIC LINE REPAIR

3-32. GENERAL

This section provides expedient repair procedures for the hydraulic system. Proce-

dures cover different methods of repair for high-

and low-pressure tubes and hoses.

3-33. HYDRAULIC TUBE AND HOSE REPAIR

General Information:

These procedures tell how to repair damaged hydraulic tubes and hoses. Use the

following options to repair any damaged hydraulic tube or hose. To repair high-

-pressure lines use only the high-pressure options recommended. High-pressure proce-

dures also may be used for low-pressure line fixes if the situation calls for it.

Personnel/Time Required:

Materials/Tools:

o 1 soldier

o Correct size hydraulic

o 25 to 40 minutes

hose or tubing

o Hose clamps

o Sealing compound

o Adhesive tape

o Hacksaw

o Nipples

Option 1:

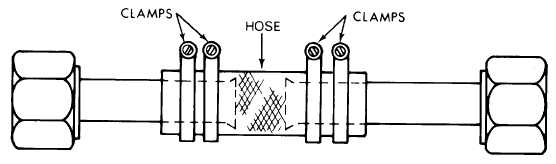

Tube Repair with a Rubber Hose.

Limitations:

o Not recommended for pressure above 70 psi

Procedural Steps:

1.

Squarely cut each end of damaged tube.

Flare each end of damaged tube, if

possible, and remove burrs.

2.

Measure and record distance between cut ends of damaged tube.

3.

Cut a length of correct diameter rubber hose 6 inches longer than distance

measured.

4.

Spread a light coat of sealing compound inside rubber hose.

5.

Position hose between flared tube ends and secure each end with two clamps.

3-27

|