|

| |

TM 9-2320-356-BD

4.

Adjust the regulator to zero pressure by turning adjustment knob fully

counterclockwise.

5.

Adapt a l/4-inch air hose from the nitrogen or argon bottle to the emergency

air line on the rear of the truck.

6.

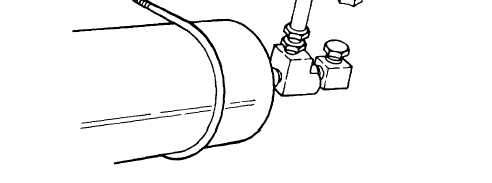

Disconnect the main air supply line from the

primary air tank.

7.

Use the same size fitting, that is used on

the main air supply line, and a 6-inch piece of

copper tubing to plug off the primary air tank.

Double crimp the copper tubing.

8.

Open the valve on the bottle.

9.

Adjust the regulator for 100 psi.

10. Check air gage in the vehicle for a pressure reading.

11. Drive the vehicle a short distance and check braking.

12. Periodically check pressure in

13. Record the BDAR action taken.

practicable,

repair using standard

11-14.

AIR GOVERNOR FAILURE

the nitrogen or argon bottle.

When the mission is completed, as soon as

maintenance procedures.

The governor maintains air pressure in the reservoir between the desired maximum

and minimum values by controlling the compressor unloading mechanism.

If the

governor failed, maintaining a constant working air pressure would be impossible.

Limitations:

o None

Personnel/Time Required:

o 1 soldier

o 1 hour

Materials/Tools:

o Pipe plug

o New or used replacement

governor

11-10

|