|

| |

TM 9-2320-356-BD

6.

Refill coolant to proper level.

7 .

Check for leaks.

8.

Record the BDAR action taken.

When the mission is completed, as soon as

practicable, repair using standard maintenance procedures.

7-14.

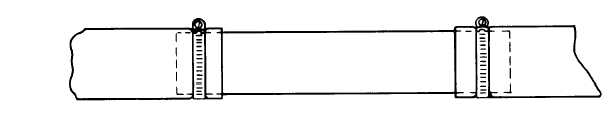

HOSE IMPROVISATION (LOW PRESSURE)

General Information:

Coolant hose or tube damage will sometimes be such that a patch will not stop the

leak.

The damaged portion must be removed and replaced with a substitute. Several

repairs can be made using one of the following procedures.

Limitations:

o None

Personnel/Time Required:

o 1 soldier

o 15-60 minutes

Materials/Tools:

o Gasket sealer

o Garden hose, heater hose

o Pipe

o Clamps or wire

o Hacksaw

Procedural Steps:

Option 1:

Pipe Insert.

1.

Cut out damaged hose section.

2.

Cut a piece of pipe longer than the damaged hose section.

3.

Coat the pipe ends with gasket sealer.

4.

Insert the pipe

5.

Secure the hose

6.

Fill coolant to

7.

Record the BDAR

into the damaged hose ends.

ends with clamps or twisted wire.

proper level and check for leaks.

action taken.

When the mission is completed, as soon as

practicable, repair using standard maintenance procedures.

7-13

|