|

|||

|

|

|||

|

Page Title:

Illustration 216 Schematic Drawing |

|

||

| ||||||||||

|

|

86

TM 9-2320-312-24-2

Truck Engine

Disassembly and Assembly Section

5. Replace rod bearing (6) by pressing a new

bearing into the connecting rod. Refer to Special

NOTICE

Instruction, SEHS7295 for the correct tooling and

Verify correct assembly of the pistons and the con-

the correct installation procedure.

necting rods. Ensure that the etched numbers on the

rod and the rod cap are in the correct positions. The

etched number on the rod and the rod cap correspond

to the cylinder in which it should be installed.

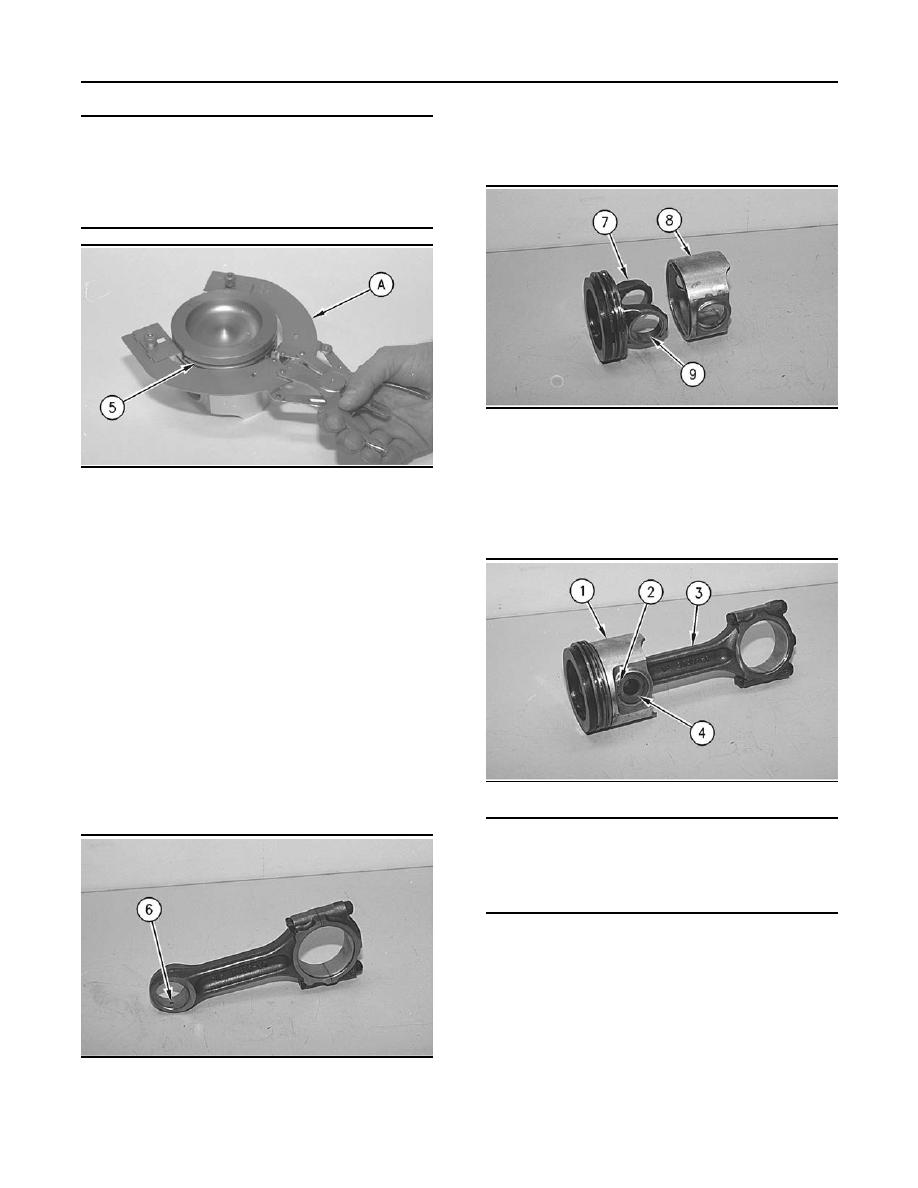

g00610503

Illustration 218

6. The piston is a two-piece assembly. This piston

consists of piston crown (7) and piston skirt (8).

g00610428

Illustration 216

Inspect bearing (9) in the piston crown (7). The

piston crown must be replaced if the piston

1. Check the clearance between the ends of piston

crown is worn or damaged. Bearing (9) is not

rings (5). Refer to the Specifications Manual,

serviced.

"Pistons and Rings" topic.

Note: The oil ring must be installed over the spring

with the end gap 180 degrees from the oil ring

spring joint.

2. Install the oil control piston ring with Tool (A).

The ends of the spring should be rotated 180

degrees from the ring end gap.

3. Install the intermediate piston ring with the side

marked "UP-2" toward the top of the piston. Use

Tool (A) in order to install the ring.

4. Install the top piston ring with the side marked

g00610426

"UP-1" toward the top of the piston. Use Tool (A)

Illustration 219

in order to install the ring.

NOTICE

An improperly installed retainer ring could cause the

piston and connecting rod to come apart during en-

gine operation. This action can result in a broken Pis-

ton Skirt and major engine damage.

7. Position piston (1) on connecting rod (3). Coat

pin (4) with clean engine oil and install pin (4).

Ensure that the retainer rings are in the grooves

of piston (1).

End By:

g00610498

Refer to Disassembly and Assembly, "Piston and

Illustration 217

Connecting Rods - Install".

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |