|

|||

|

|

|||

|

Page Title:

Steps For Cleaning The Carbon Deposits |

|

||

| ||||||||||

|

|

11

TM 9-2320-312-24-2

Truck Engine

Disassembly and Assembly Section

Steps For Cleaning The Carbon Deposits

g00778868

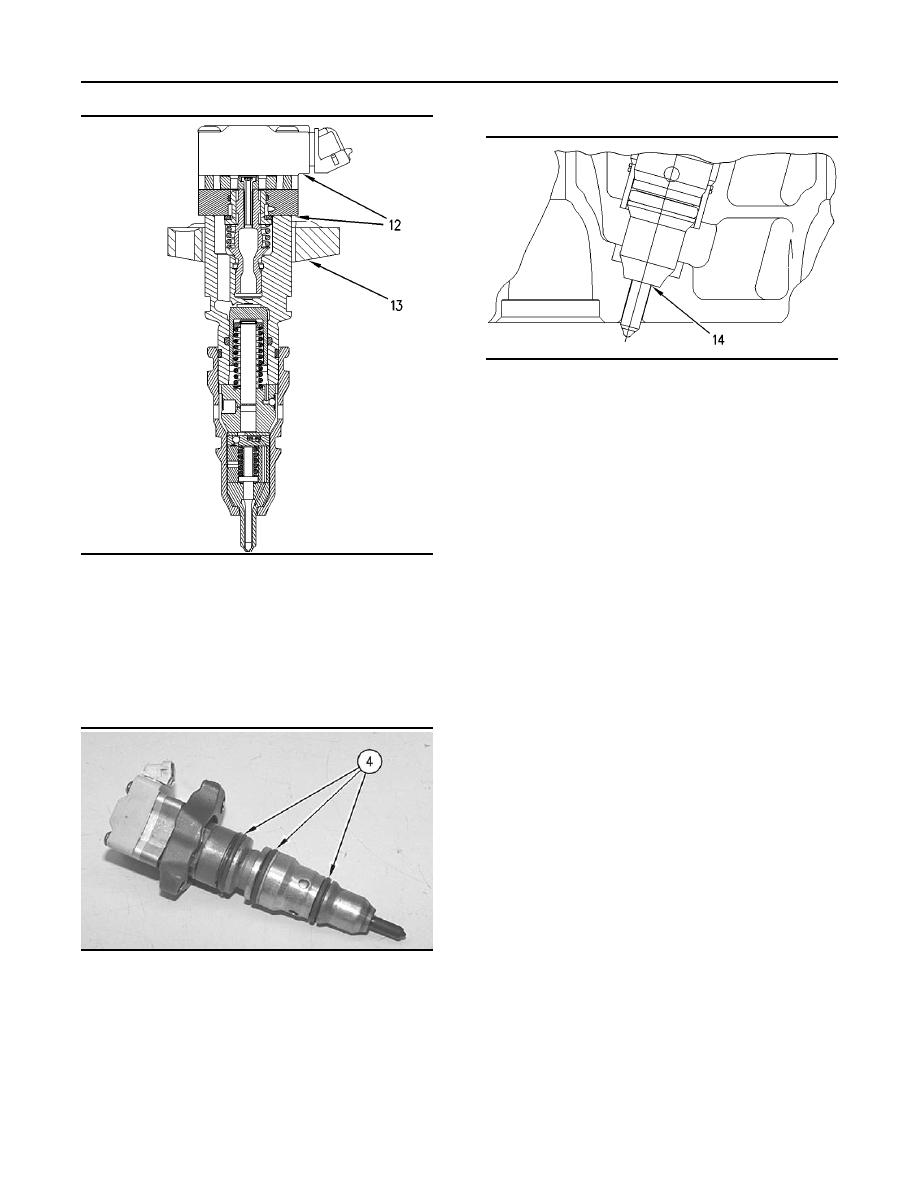

Illustration 23

(14) Metal Seal

Cleanliness is very important in the area around the

sleeve and the sleeve bore when you are reinstalling

the injector. This injector has a metal seal between

the bottom of the injector's case and a seat in the

cylinder head. Unlike the former designs which

were seated against a brass sleeve, this injector

seats in the cylinder head. Clean the carbon from

the seat area that is inside of the cylinder head.

Also clean the carbon from the end of the injector if

g00778851

Illustration 21

the injector should be reinstalled.

(12) Do not pry here.

The fine grade of the Scotch Brite material is

(13) Tool (A) should be placed at this location in order to gently

remove the injector.

preferred. Scotch Brite is available from the Tools

And Shop Products Guide as the 1U-5512 Cut &

6. Place Tool (A) under the clamp (13) on the

Polish Roll and as the 8T-7765 Hand Pad.

flywheel side of the injector.

If the sleeve of the injector has been removed from

7. Use Tool (A) to remove the injector.

the engine, use a 9U-6102 Reamer to remove

carbon deposits from the angled surface.

Note: Do not use the 9U-6102 Reamer in order to

remove metal from the sleeve. Use the 9U-6102

Reamer in order to remove carbon only.

If the sleeve of the injector is installed in the engine,

use the 4C-6161 Tube Brush to clean the carbon

deposits from the inside of the sleeve.

If you choose to clean the angled seat on the

injector with a wire brush, the wire brush should not

contact the tip of the injector. Failure of the tip and

major engine damage may result.

g00294208

Illustration 22

Note: Using power tools in order to rotate the

material should not be necessary. The carbon in

(4) O-Ring Seals

the sleeve is more removable than the carbon at

8. Remove the O-Ring seals (4) from the injector.

locations that are exposed to higher temperatures.

9. Repeat Step 4 through Step 8 for the remainder

The following procedure is the preferred method of

of the injectors.

cleaning the sleeve bore.

1. Place a 38 mm (1.5 inch) square piece of Scotch

Brite material on the end of a 9U-6862 Tapered

Brush.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |