|

|||

|

|

|||

|

Page Title:

Test Step 1. Inspect Electrical Connectors and Wiring |

|

||

| ||||||||||

|

|

422

TM 9-2320-312-24-2

Troubleshooting Section

Expected Result:

All connectors, pins and sockets should be

completely coupled and/or inserted and the harness

and wiring should be free of corrosion, abrasion

or pinch points.

Results:

OK Proceed to Test Step 2.

Not OK

Repair: Repair the connectors or wiring and/or

replace the connectors or wiring. Ensure that all

of the seals are properly in place and ensure that

the connectors are completely coupled.

STOP.

Test Step 2. Check for Normal Operation

of the Warning Lamp.

A. Monitor the warning lamp. Turn the ignition key

switch to the ON position, while the engine is

OFF. The lamp should turn on for five seconds.

Then, the lamp should turn off.

The lamp will continue flashing if there is an

active diagnostic code. If there is an active

diagnostic code, connect ET in order to read

the active diagnostic code. Troubleshoot the

problem.

Note: The warning lamp will not turn on until the

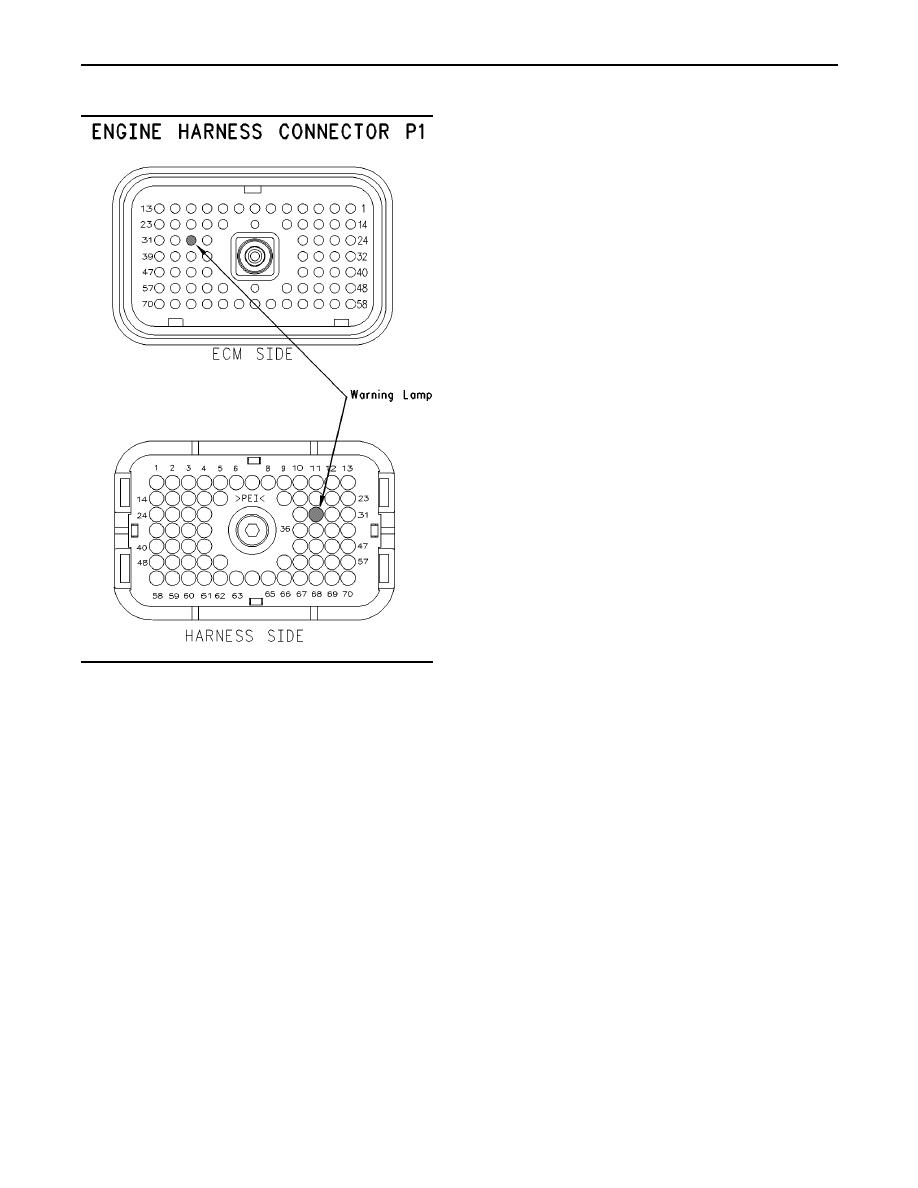

g00769348

Illustration 194

engine is cranked.

Pin locations for the Warning Lamp circuit

B. Connect ETto the cab data link connector.

Test Step 1. Inspect Electrical Connectors

Verify that the "Engine Monitoring" has been

and Wiring.

programmed to "WARNING", "DERATE",

or "SHUTDOWN". If "Engine Monitoring" is

A. Thoroughly inspect ECM vehicle harness

programmed to "OFF", the warning lamp is not

connector J1/P1, the firewall bulkhead connector,

used and the ECM will not turn on the lamp.

and terminal 29. Refer to Illustration 194. Refer

to Troubleshooting, "Electrical Connectors -

While the warning lamp is being observed, start

Inspect" for details.

the engine. The warning lamp should turn on

for a minimum of two seconds after the engine

B. Perform a 45 N (10 lb) pull test on each of the

starts. Then, the warning lamp should turn off.

wires in the ECM connector that is associated

If the lamp remains off, immediately shut down

with the suspect terminal for the lamp.

the engine.

C. Check the ECM connector (allen head screw) for

Expected Result:

the proper torque of 6.0 Nm (55 lb in).

The warning lamp turns on and the warning lamp

D. Check the harness and wiring for abrasion and

turns off per the above description.

pinch points from the battery to the ECM.

Results:

OK The lamp appears to operating correctly

at this time. STOP.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |