|

|||

|

|

|||

|

Page Title:

Test Step 2. Inspect Electrical Connectors and Wiring |

|

||

| ||||||||||

|

|

183

TM 9-2320-312-24-2

Troubleshooting Section

Test Step 2. Inspect Electrical Connectors

"Low Cruise Control Speed Set Limit"

and Wiring.

"High Cruise Control Speed Set Limit"

Idle Parameters

"Fast Idle RPM #1"

"Fast Idle RPM #2"

"Idle Vehicle Speed Limit"

"Idle RPM Limit"

"Top Engine Limit" (TEL)

PTO Parameters

"PTO Configuration"

"PTO Kickout Vehicle Speed Limit"

D. Ensure that the vehicle is not experiencing

a problem due to one of these parameters.

Refer to Troubleshooting, "Customer Specified

Parameters" for a description of the parameters,

if necessary.

E. Check the status screen that indicates the last

cause of a kickout for one of the following modes:

Cruise Kickout

Idle Kickout

Fast Idle Kickout

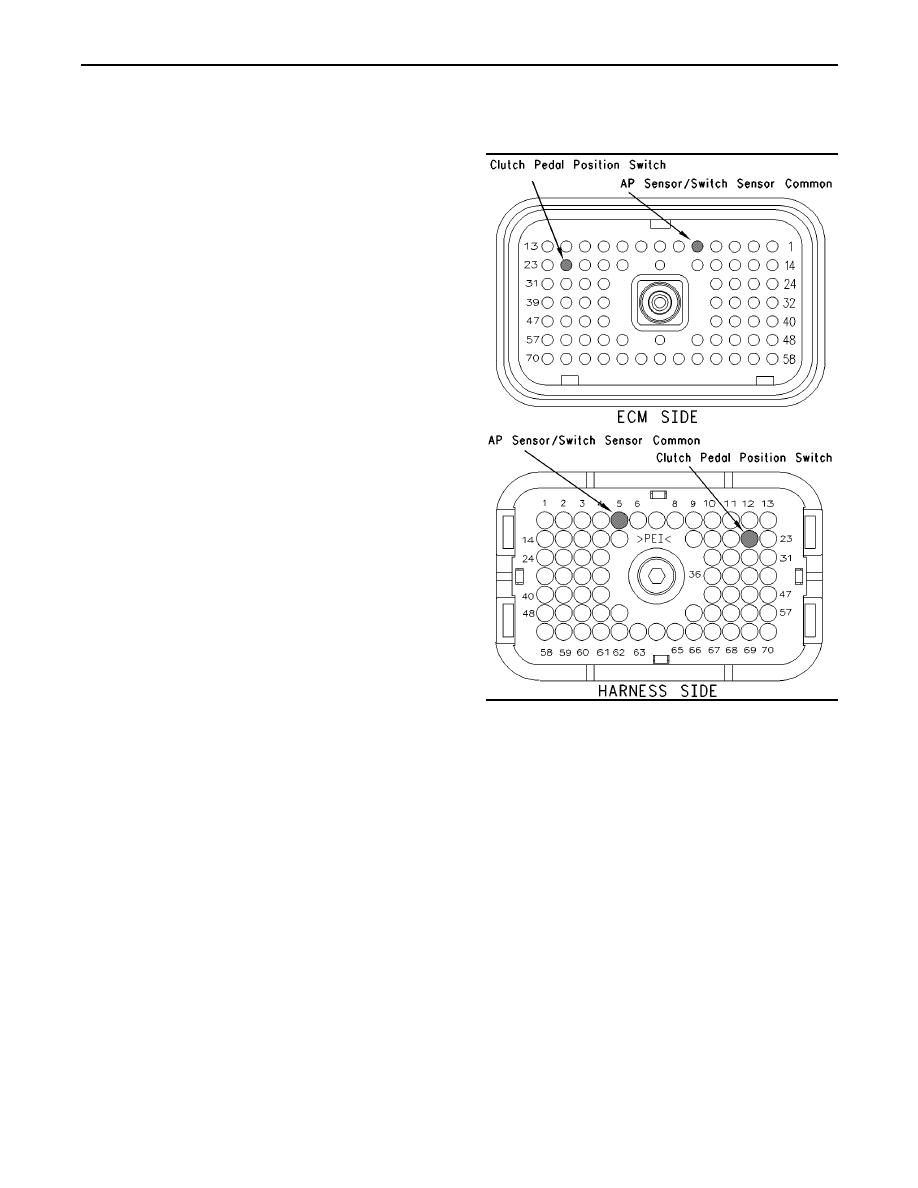

g00773080

Illustration 50

PTO Kickout

A. Thoroughly inspect ECM vehicle harness

Refer to Tables 145, 146, 147, and 148 for the

connector J1/P1, the firewall bulkhead connector

meaning of the status screen.

and the terminals for the following switches in

the connectors:

Expected Result:

clutch pedal position switch (terminal 22)

The problem is due to a parameter setting or the

problem is due to a normal kickout.

AP sensor/switch sensor common (terminal 5)

Results:

Refer to Troubleshooting, " Electrical Connectors

- Inspect" for details.

Yes Explain the proper operation of system to

the driver. STOP.

B. Perform a 45 N (10 lb) pull test on each of the

wires in the ECM connector that are associated

No

with the switches.

Repair: Refer to Tables 145, 146, 147, and 148 for

Refer to Illustration 50.

recommended troubleshooting.

C. Check the ECM connector (allen head screw) for

If a problem is still suspected with the clutch

the proper torque of 6.0 Nm (55 lb in).

switch circuit perform the following procedure:

D. Check the harness and wiring for abrasion and

Proceed to Test Step 2.

pinch points from the sensor to the ECM.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |