|

|||

|

|

|||

|

Page Title:

Testing The Radiator And Cooling System For Leaks |

|

||

| ||||||||||

|

|

93

TM 9-2320-312-24-2

Testing and Adjusting Section

3. Look at the gauge for the exact pressure that

opens the filler cap.

4. Compare the gauge's reading with the opening

pressure that is listed on the filler cap.

5. If the filler cap is damaged, replace the filler cap.

Testing The Radiator And Cooling

System For Leaks

Table 21

Tools Needed

g00296067

Part

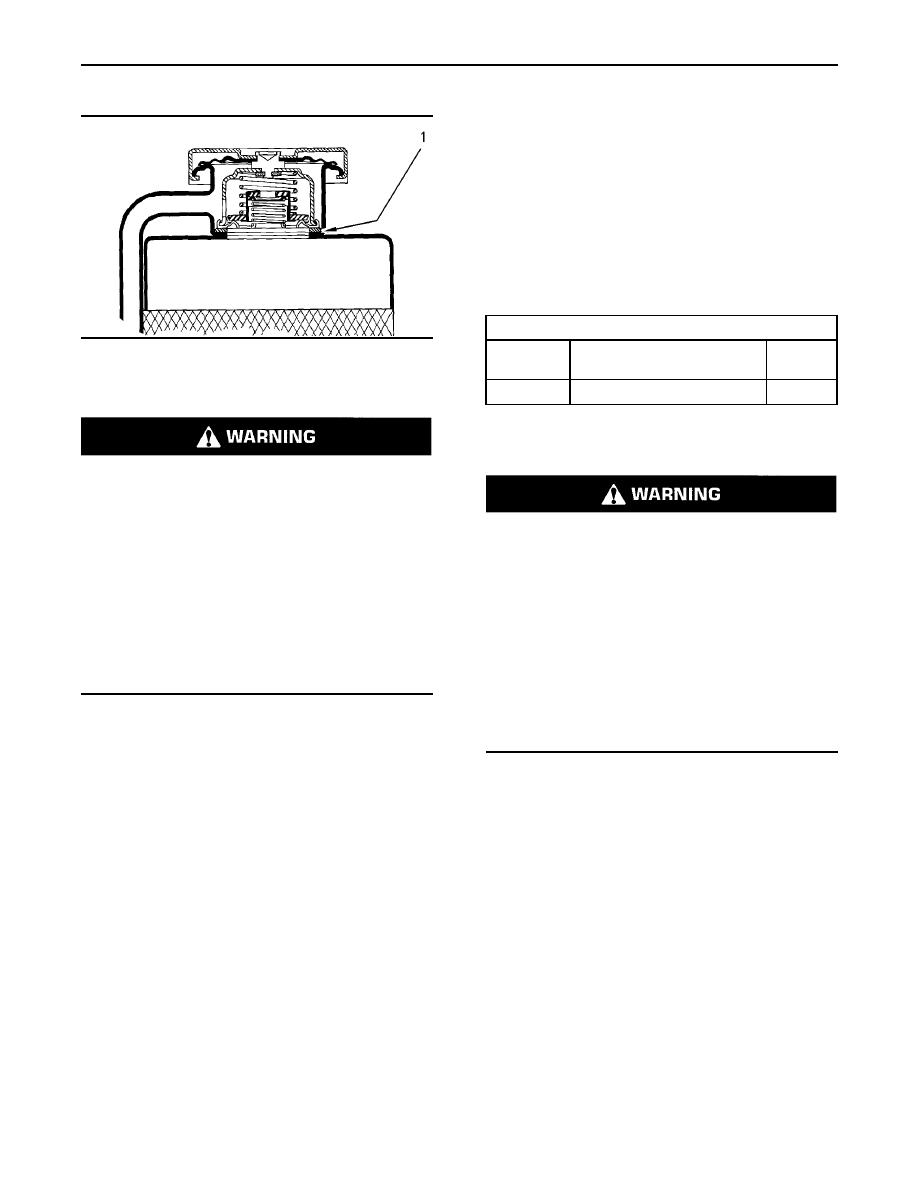

Illustration 75

Part Name

Quantity

Number

Typical schematic of filler cap

1

9S-8140

Pressurizing Pump

(1) Sealing surface of both filler cap and radiator

Use the following procedure in order to check the

cooling system for leaks:

Personal injury can result from hot coolant, steam

and alkali.

At operating temperature, engine coolant is hot

Personal injury can result from hot coolant, steam

and under pressure. The radiator and all lines

and alkali.

to heaters or the engine contain hot coolant or

steam. Any contact can cause severe burns.

At operating temperature, engine coolant is hot

and under pressure. The radiator and all lines

Remove filler cap slowly to relieve pressure only

to heaters or the engine contain hot coolant or

when engine is stopped and radiator cap is cool

steam. Any contact can cause severe burns.

enough to touch with your bare hand.

Remove filler cap slowly to relieve pressure only

Cooling System Conditioner contains alkali. Avoid

when engine is stopped and radiator cap is cool

contact with skin and eyes.

enough to touch with your bare hand.

Cooling System Conditioner contains alkali. Avoid

To check for the amount of pressure that opens the

contact with skin and eyes.

filler cap, use the following procedure:

1. After the engine cools, carefully loosen the filler

1. After the engine is cool, loosen the filler cap

cap. Slowly release the pressure from the cooling

slowly and allow pressure out of the cooling

system. Then, remove the filler cap.

system. Then remove the filler cap from the

radiator.

Carefully inspect the filler cap. Look for any

damage to the seals and to the sealing surface.

2. Ensure that the coolant level is above the top of

Inspect the following components for any foreign

the radiator core.

substances:

3. Install the 9S-8140 Pressurizing Pump onto the

Filler cap

radiator.

Seal

4. Take the pressure reading on the gauge to

20 kPa (3 psi) more than the pressure on the

Surface for seal

filler cap.

Remove any deposits that are found on these

5. Check the radiator for leakage on the outside.

items, and remove any material that is found on

these items.

6. Check all connection points for leakage, and

check the hoses for leakage.

2. Install the filler cap on the 9S-8140 Pressurizing

Pump.

The cooling system does not have leakage only if

the following conditions exist:.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |