|

|||

|

|

|||

|

Page Title:

Valve Lash and Valve Bridge Adjustment |

|

||

| ||||||||||

|

|

80

TM 9-2320-312-24-2

Testing and Adjusting Section

Valve Lash and Valve Bridge

a. Lightly tap the rocker arm at the top of the

adjustment screw with a soft mallet. This will

Adjustment

ensure that the lifter roller seats against the

camshaft's base circle.

b. Loosen the adjustment locknut.

c. Place the appropriate feeler gauge between

rocker arm and the valve bridge. Then, turn

the adjustment screw in a clockwise direction.

Slide the feeler gauge between the rocker arm

and the valve bridge. Continue turning the

adjustment screw until a slight drag is felt on

the feeler gauge. Remove the feeler gauge.

of 30 7 Nm (22 5 lb ft). Do not allow

the adjustment screw to turn while you are

tightening the adjustment locknut. Recheck

the valve lash after tightening the adjustment

locknut.

3. Remove the timing bolt and turn the flywheel by

360 degrees in the direction of engine rotation.

g00942236

This will put the No. 6 piston at the top center

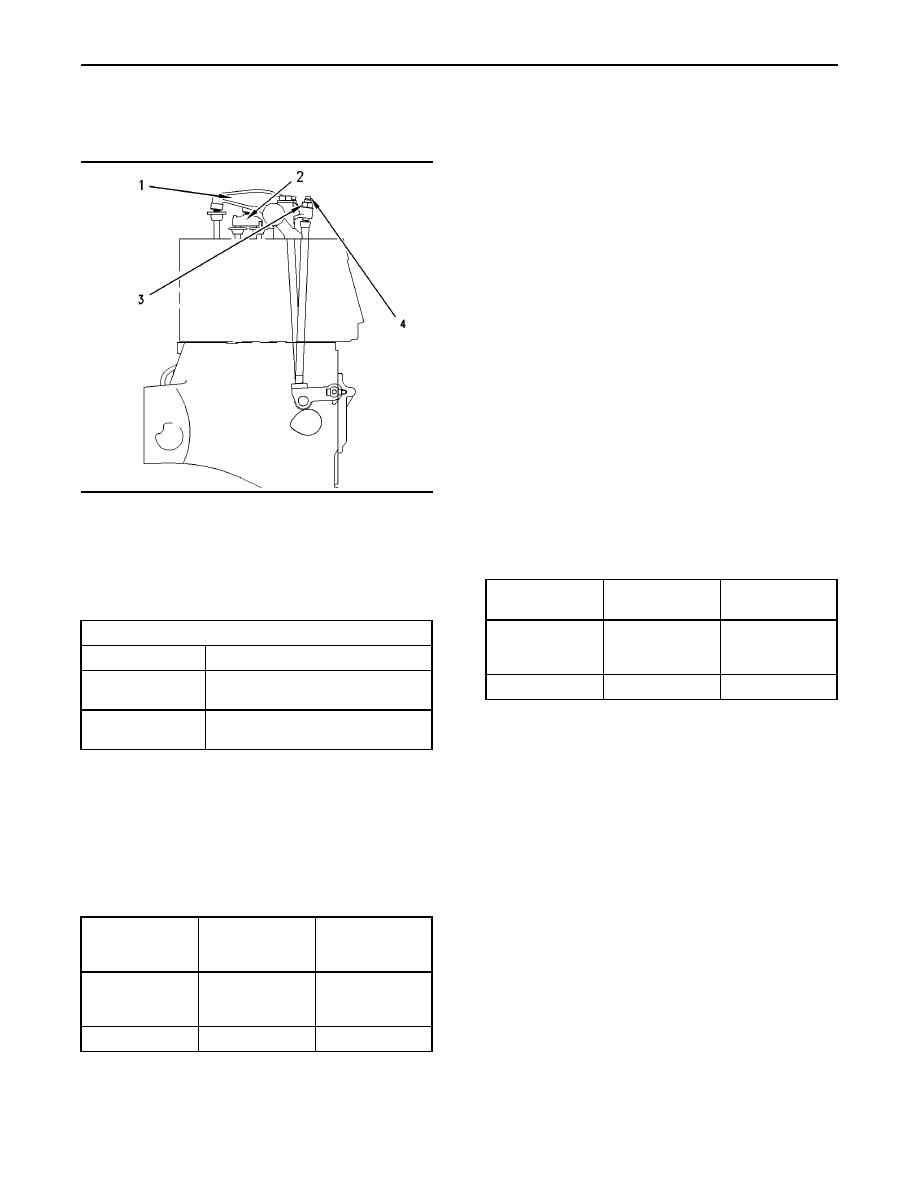

Illustration 64

position on the compression stroke. Install the

(1) Exhaust rocker arm

timing bolt in the flywheel.

(2) Inlet valve bridge

(3) Rocker arm adjustment screw locknut for the exhaust rocker

arm

Table 16

(4) Rocker arm adjustment screw for the exhaust rocker arm

TC Exhaust

Inlet Valves

Exhaust Valves

Stroke(3)

Table 14

0.38 0.08 mm

0.64 0.08 mm

Valve Lash

(0.0150 0.0031

(0.0252 0.0031

Valve Lash

Valves

Dimension of Gauge

inch)

inch)

0.38 0.08 mm

3-5-6

2-4-6

Cylinders

Inlet

(0.0150 0.0031 inch)

(3)

Position for No. 1 cylinder

0.64 0.08 mm

Exhaust

(0.0252 0.0031 inch)

4. Adjust the valve lash according to Table 16.

a. Lightly tap the rocker arm at the top of the

Adjust the valve lash while the engine is stopped.

adjustment screw with a soft mallet. This will

Use the following procedure to adjust the valves:

ensure that the lifter roller seats against the

camshaft's base circle.

1. Put the No. 1 piston at the top center position

on the compression stroke. Refer to Testing and

b. Loosen the adjustment locknut.

Adjusting, "Finding Top Center Position for No.

1 Piston".

c. Place the appropriate feeler gauge between

rocker arm and the valve bridge. Then, turn

Table 15

the adjustment screw in a clockwise direction.

TC

Slide the feeler gauge between the rocker arm

Inlet Valves

Exhaust Valves

Compression

and the valve bridge. Continue turning the

Stroke

adjustment screw until a slight drag is felt on

0.38 0.08 mm

0.64 0.08 mm

the feeler gauge. Remove the feeler gauge.

(0.0150 0.0031

(0.0252 0.0031

Valve Lash

inch)

inch)

1-2-4

1-3-5

Cylinders

2. Adjust the valve lash according to Table 15.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |