|

|||

|

|

|||

|

Page Title:

Valve Operation for ENGINE CRANKING |

|

||

| ||||||||||

|

|

26

TM 9-2320-312-24-2

Systems Operation Section

When the engine is off, there is no pump outlet

pressure (1) from the pump and there is no current

to the solenoid from the ECM (2). The spool spring

pushes the spool valve completely to the left. When

the spool spring pushes the spool valve completely

to the left, drain port (3) is completely blocked.

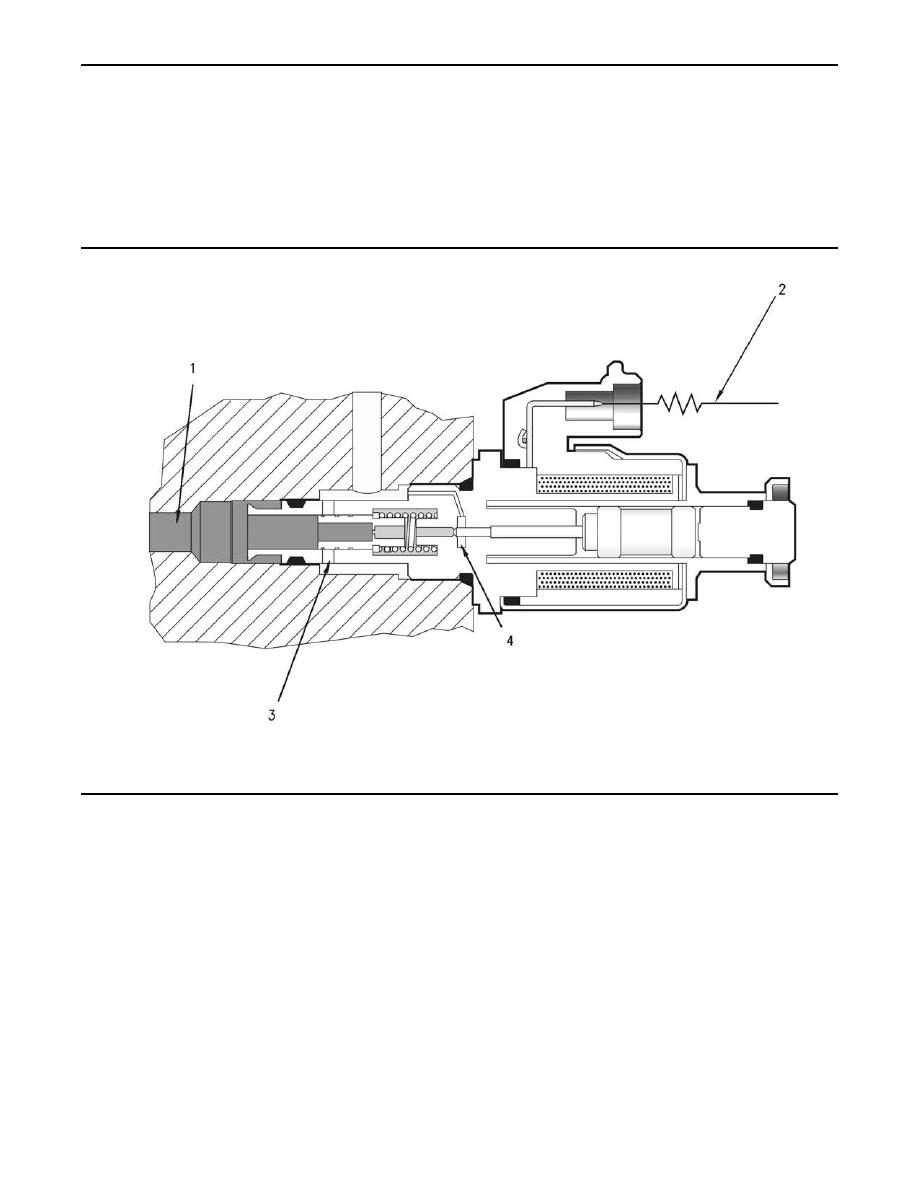

Valve Operation for ENGINE CRANKING

g00295337

Illustration 13

Operation of the injection actuation pressure control valve (engine cranking)

(1) Pump outlet pressure

(3) Drain port (blocked position)

(2) Current from the ECM

(4) Poppet (closed position)

During engine start-up, approximately 6 MPa

In order to start the engine quickly, the injection

(870 psi) of injection actuation pressure is required

actuation pressure must rise quickly. Because the

in order to activate the unit injector. This low

unit injector hydraulic pump is being turned at

injection actuation pressure generates a low fuel

engine cranking speed, pump flow is very low. The

injection pressure of about 35 MPa (5000 psi). This

ECM sends a strong current (2) to the IAP Control

low fuel injection pressure aids cold starting.

Valve in order to keep the spool closed. With

the spool in the closed position, all of the flow to

drain port (3) is blocked. The flow to drain port (3)

remains blocked until the actual actuation pressure

of 6 MPa (870 psi) is reached. The unit injectors are

not fired until the 6 MPa (870 psi) actual actuation

pressure is reached.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |